Blast Chiller Temperature Record Sheet

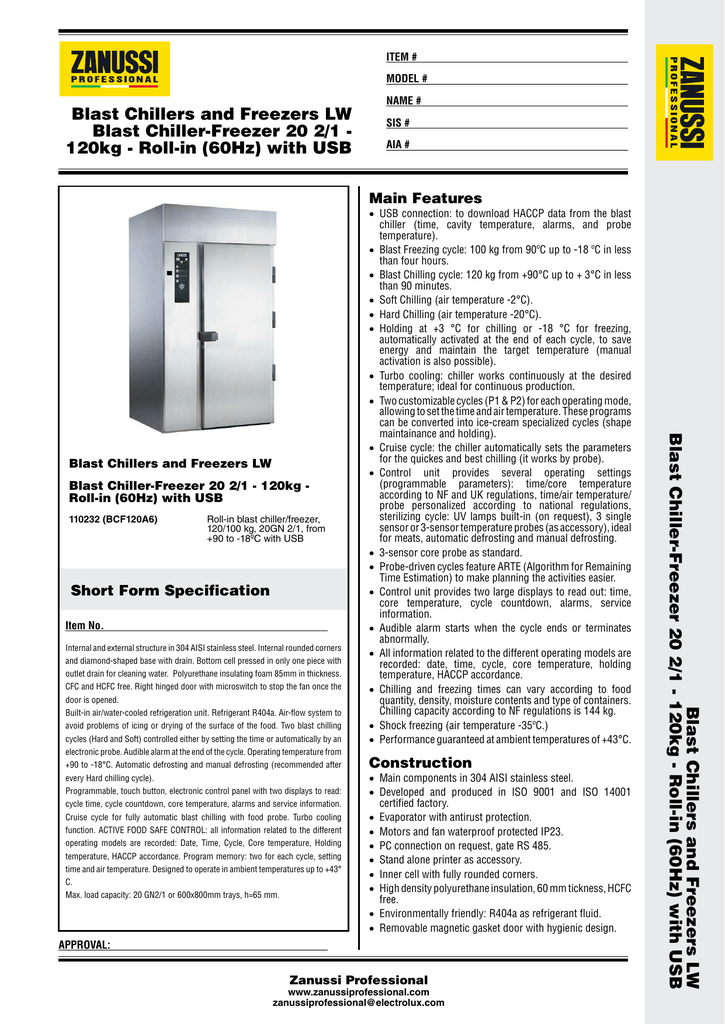

NOTE The BE1 requires the blast chiller to be used with the Angelo Po FX Combistar combi oven Angelo Po also offers Blitz, selfcontained standalone models of blast chillers/freezers Irinox MODEL MF1002 SC Blast Chiller/Shock Freezer PLUS CYCLES Blast chill, shock freeze, hold, lowtemperature cook, proof, thaw, regenerate, pasteurize.

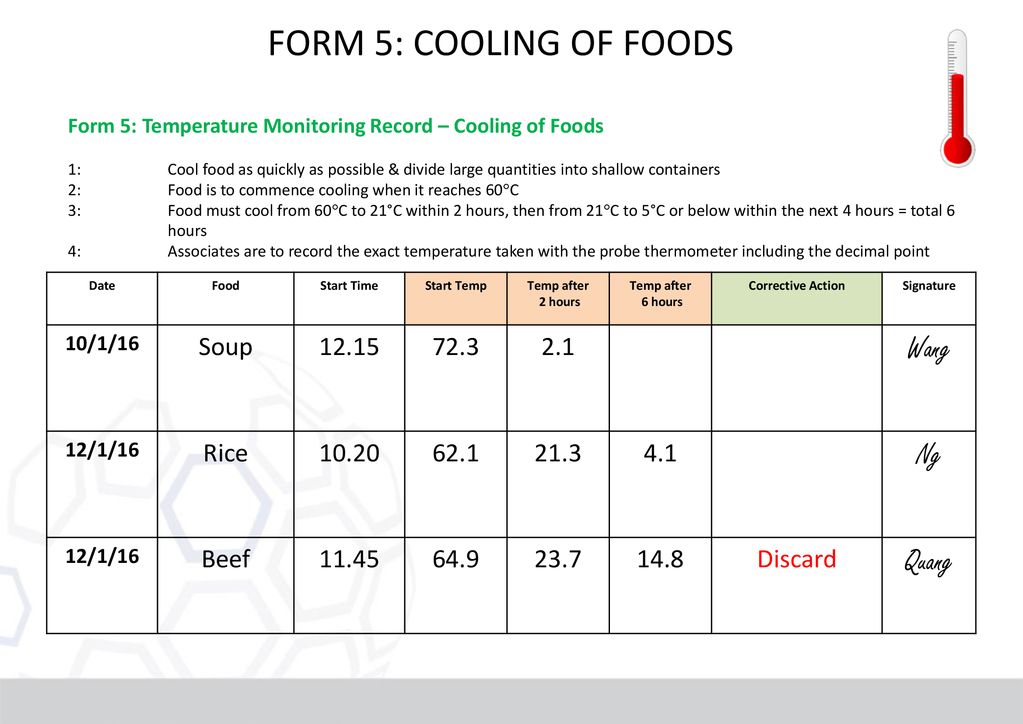

Blast chiller temperature record sheet. Consider risks to staff, customers, visitors, contractors & members of the public Use and Cleaning of Blast Chiller 2Freezer Burns 3Use of Chemicals 4Electricity 5Environment 61b;62 Ensure load is within your personal handling capabilities Gloves to be worn when working in freezer Coshh training must have been completed. Safe Catering Pack A User Friendly Approach to HACCP What is the Safe Catering Pack The Safe Catering Pack is a tool to help caterers develop a system to manage food safety and comply with the food hygiene regulations. Once the temperature has dropped below 63 degrees, record the temperature the probe settles at onto the baking and cooling sheet Move the racks into blast chiller and insert a probe into a Pattie.

Blast chillers are indispensable tools for chefs, since they give restaurateurs the opportunity of planning and organizing their activity in advance, offering customers a full and varied menu, fast and efficient Te c nomac blast freezer lowers the temperature at the core of the food to 18 ° C in under 240 min, a. A blast chiller is the quickest and safest way to do this to prevent bacterial development Check your temperatures A temperature monitoring system is essential for any cold storage unit but it is also essential to regularly check and record internal temperatures manually. Once the temperature has dropped below 63 degrees, record the temperature the probe settles at onto the baking and cooling sheet Move the racks into blast chiller and insert a probe into a Pattie Once the temperature has dropped below 8 degrees, record the temperature once it has settled and take out the six racks from the blast chiller ready.

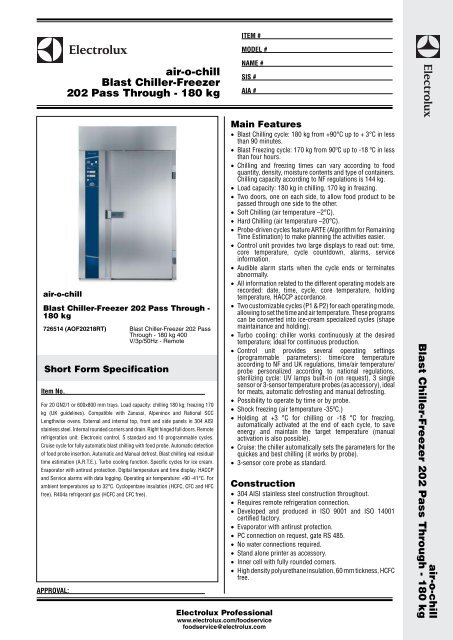

A heated core temperature probe is provided for accurate control of temperature within the product This model is compatible with and accepts the mobile oven rack directly from the Rational #101 & #102 combi ovens PERFORMANCE Blast chilling (soft or hard) lowers the food core temperature from to 100 lbs within 90 minutes or 140 lbs. • Check the core temperature with a core probe If the heart temperature set point is reached, stop cooling • Complete the blast chilling tracking sheet If the temperature and time parameters are correct, immediately store preparations in positive cold room / storage system at 3 ° C maximum (DLC D 3) Remember to. This record book should be used for recording temperatures of food cooked on your premises If the food is cooled, the time it is placed into the fridge/blast chill/blast freezer should also be.

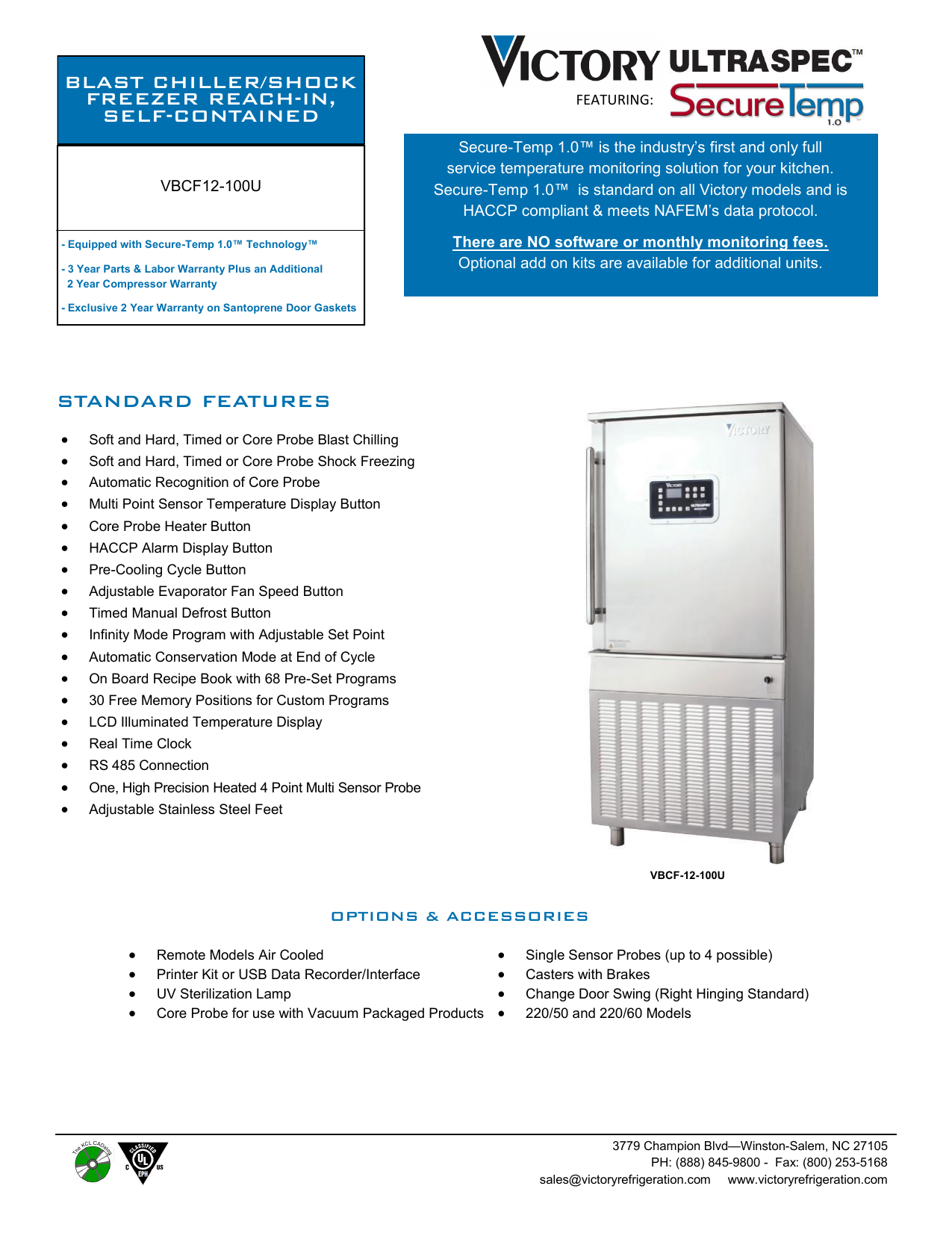

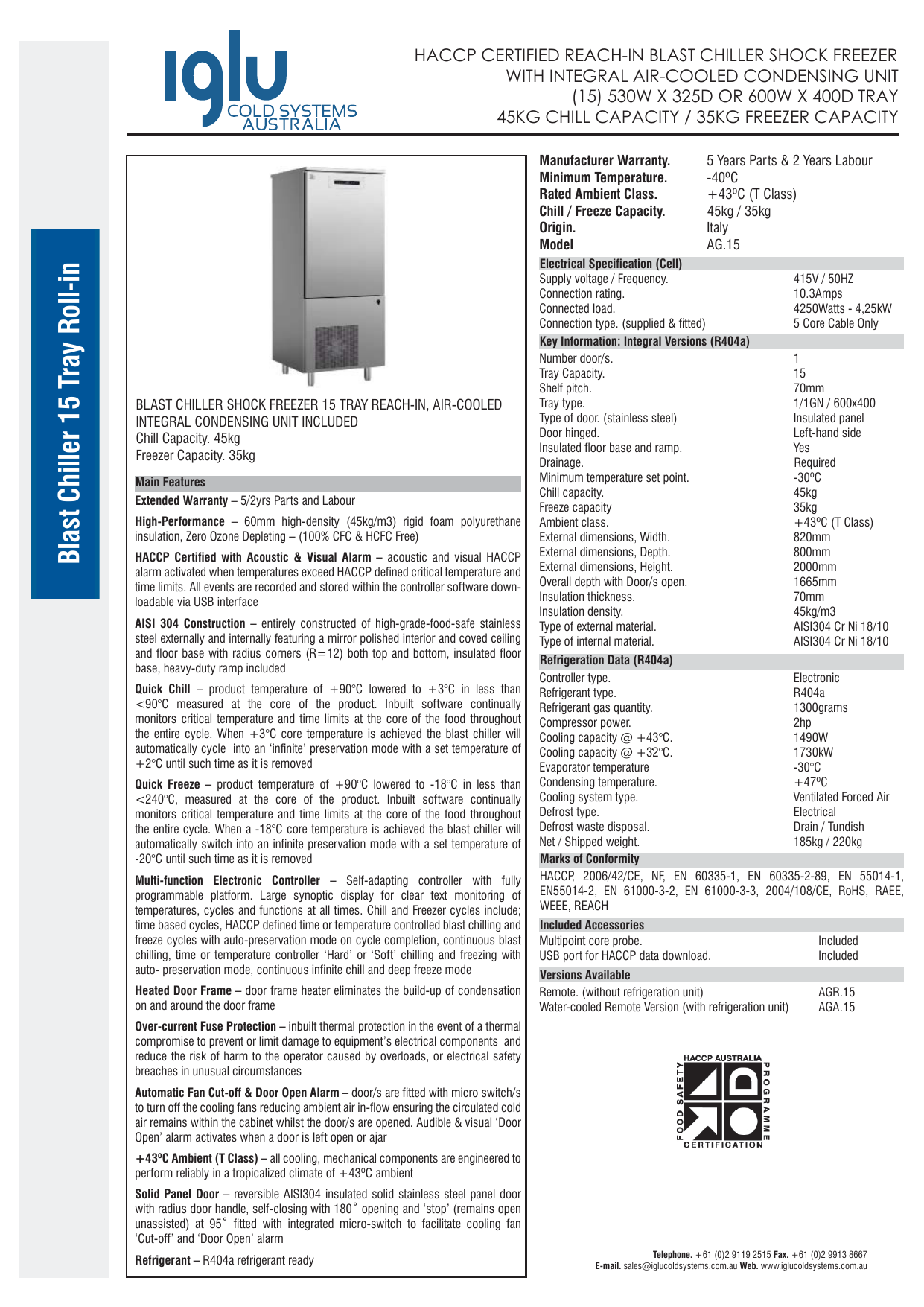

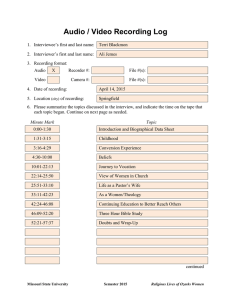

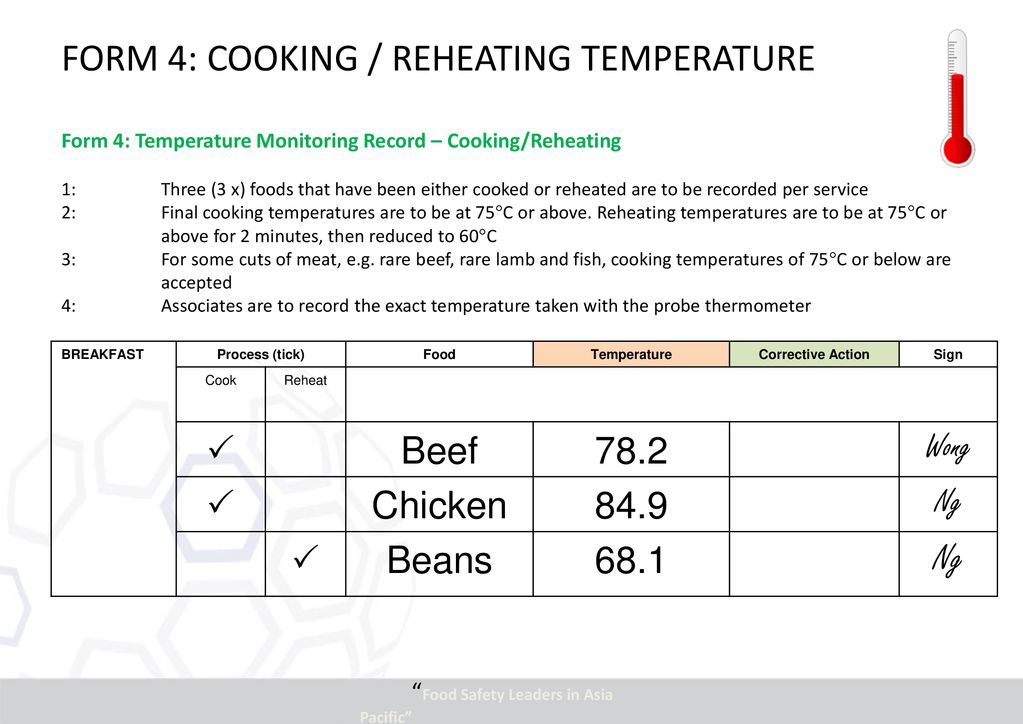

This record book should be used for recording temperatures of food cooked on your premises If the food is cooled, the time it is placed into the fridge/blast chill/blast freezer should also be recorded If the food is reheated, the date and the reheating temperature should also be recorded EC EXAMPLE Cooking* Cooling* Reheating* Comments. BLAST CHILLER SHOCK FREEZER BLAST CHILLER/SHOCK FREEZER REACHIN, SELFCONTAINED VBCF120 Victory Refrigeration specification sheets are available online at wwwvictoryrefrigerationcom low temp) recorded in memory Will record up to 10 alarm events before over writing the first alarm. 3 Check temperature of incoming meat products (2 boxes/load) Record temperatures on incoming meat invoices Reject meat products that are more than 50oF or evaluate product and cool rapidly 4 Product is to be placed in cooler or freezer immediately on racks approved for specific products 5.

Use this general employee temperature log sheet to keep a record of employees’ temperature whenever they report in for work Log as many temperature records as needed This employee temperature log sheet recognizes 1003° F as the threshold and prompts a visual cue for 1004° F and above temperature readings. BLAST CHILLER/SHOCK FREEZER ROLLIN/ ROLLTHRU 3 Year Parts & Labor Warranty Plus an Additional 2 Year Compressor WarrantyExclusive 2 Year Warranty on Santoprene Door GasketsSTANDARD FEATURES Soft and Hard, Timed or Core Probe Blast Chilling Soft and Hard, Timed or Core Probe Shock Freezing Automatic Recognition of Core Probe Multi Point Sensor Temperature Display Button. Once the temperature has dropped below 63 degrees, record the temperature the probe settles at onto the baking and cooling sheet Move the racks into blast chiller and insert a probe into a Pattie Once the temperature has dropped below 8 degrees, record the temperature once it has settled and take out the six racks from the blast chiller ready.

Page 1 The interior door liner is constructed of heavy gauge stainless steel Approvals Victory Refrigeration, Inc I 110 Woodcrest Road I Cherry Hill, NJ USA I Phone I Fax I Email sales@victoryrefrigcom ReachIn Blast Chiller VBC MODELS —. With Randell blast chillers, operators enjoy enhanced product quality, highvolume production accuracy, increased savings and — most importantly — improved food safety This category of commercial foodservice equipment is engineered to sense product temperature through a standard food probe. Documentation and easy HACCP record keeping and connectivity for temperature monitoring to NAFEM data protocol Standard Features • Two operational functions • Blast chill processing refrigerator • 38°F storage refrigerator • 123 microprocessor control panel • Blast chill cycle controlled automatically by either a food probe or.

With LCD display insures precise control of Blast Chilling (194° F to 37° F in 90 Minutes) or Shock Freezing (194° F to 0° F in 240 Minutes) Cycles One touch hard and soft automatic blast chilling or shock freezing cycles based either on core probe temperature or timed cycle. Follow the manufacture guidelines to ensure proper cooling standard is achieved and recorded appropriately. Blast Chiller Smart Chill RecordLabel Printers Service Manual (Smart Chill) Blast Chiller Training Guide (RBC50, RBC100, RBC0, RBC0RT, RBC400 & RBC400RT) G Series Freezer Service Manual.

With a Blast Chiller, it’s possible to lower the temperature of foods you have just cooked You can reduce the temperature of cooked food to 5 °C or below within 90 minutes Practically, the Blast Chiller does exactly what it sounds like It cools things down quickly, using fastmoving cold air. Correct equipment safely and hygienically if it slides, use wet paper to hold it Process Process food packs as per standard recipe specifications using correct time and temperatures Record all information Chill To chill chicken , use blast chiller Ensure the temperature is chilled to below 5 C Package Food Products Package the food products in to the correct packaging, as per the standard. Deep food pans or 18" x 26" sheet pans (pans not included) PERFORMANCE Blast chilling (soft or hard) lowers the food core temperature from 160F to 38F within 90 minutes Shock freezing lowers the food core temperature from to within 4 hours Chilling and freezing times will vary somewhat, depending on the food.

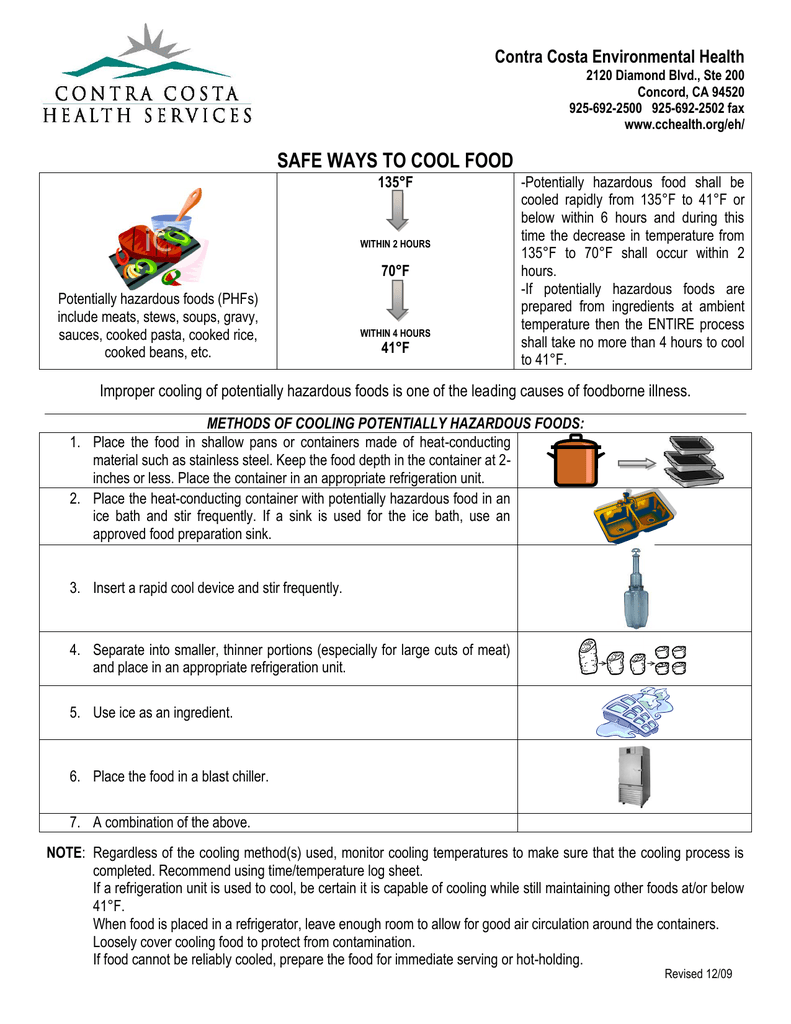

Fact Sheet Cool cooked food in the following way Food must be cooled from 135˚F to 70˚F (57˚C to 21˚C) within two hours, and from 70˚F to 41˚F (21˚C to 5˚C) or lower in the next four hours Before cooling food, reduce the quantity or size of the food you are cooling by dividing large food items into smaller portions Methods for cooling food. BLAST CHILLER / SHOCK FREEZER (SelfContained) M o d e l A P 1 2 B C F 1 1 03 Temperature Recorder A strip recorder provides a record of the unit’s operating parameters during a cycle and the following holding period The information recorded includes date, time, cycle identification, recipe. Blast Chiller Smart Chill RecordLabel Printers Service Manual (Smart Chill) Blast Chiller Training Guide (RBC50, RBC100, RBC0, RBC0RT, RBC400 & RBC400RT) G Series Freezer Service Manual.

The correct temperature, ie 8°C or colder for chilled food (best at 25°C) and 18°C or colder for frozen food You must record the delivery temperatures so that you can show that the food was delivered at the correct temperatures To avoid puncturing packaging you should take a temperature between packs or using an infrared thermometer. BLAST CHILLERS basic service guide Table of Contents Defrost will not occur until all food probes have reached target temp (DONE) a Chiller completed chill cycle for all probes Retrieve cycle data after defrost Record Paper p/n , Labels p/n. With Randell blast chillers, operators enjoy enhanced product quality, highvolume production accuracy, increased savings and — most importantly — improved food safety This category of commercial foodservice equipment is engineered to sense product temperature through a standard food probe.

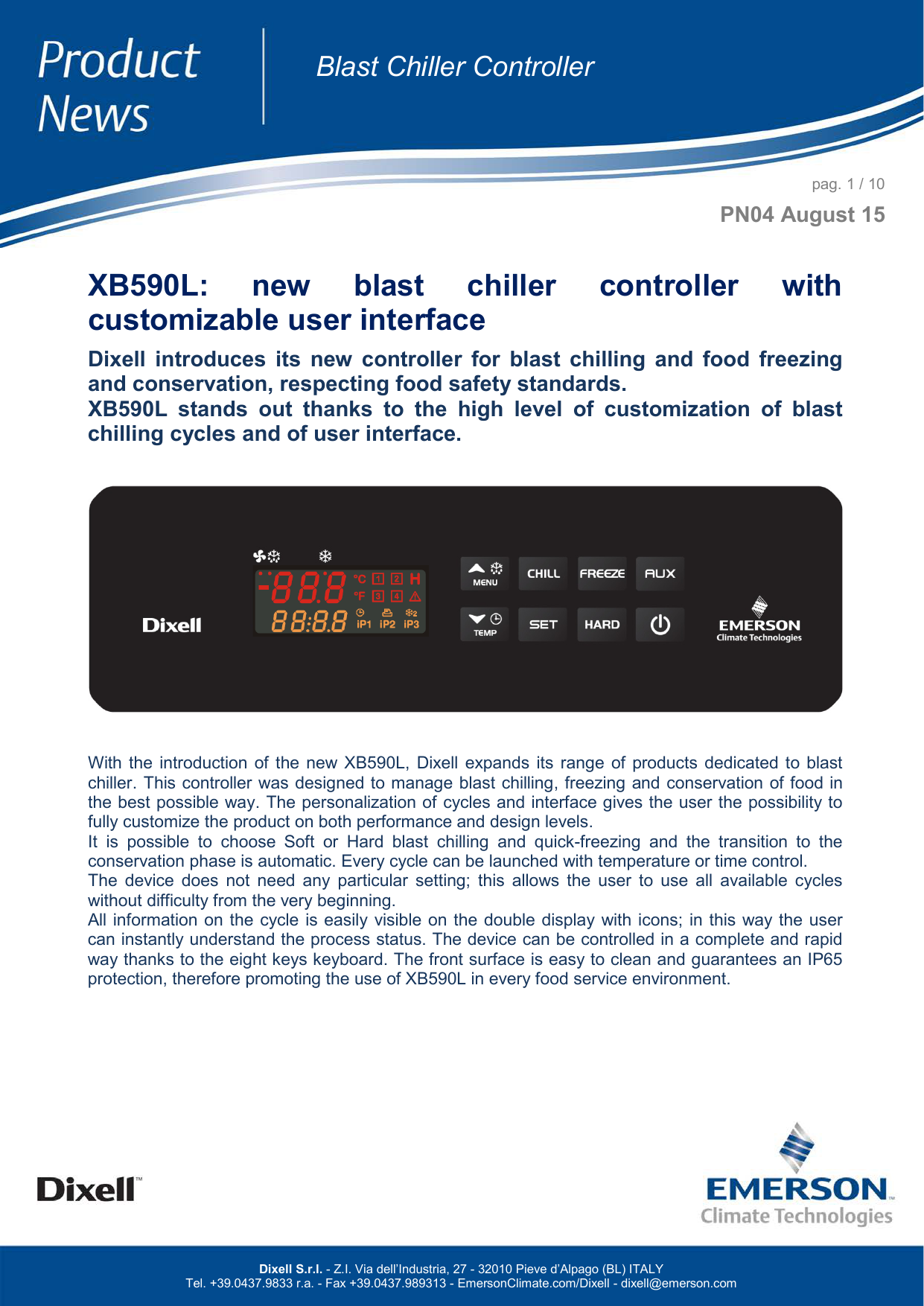

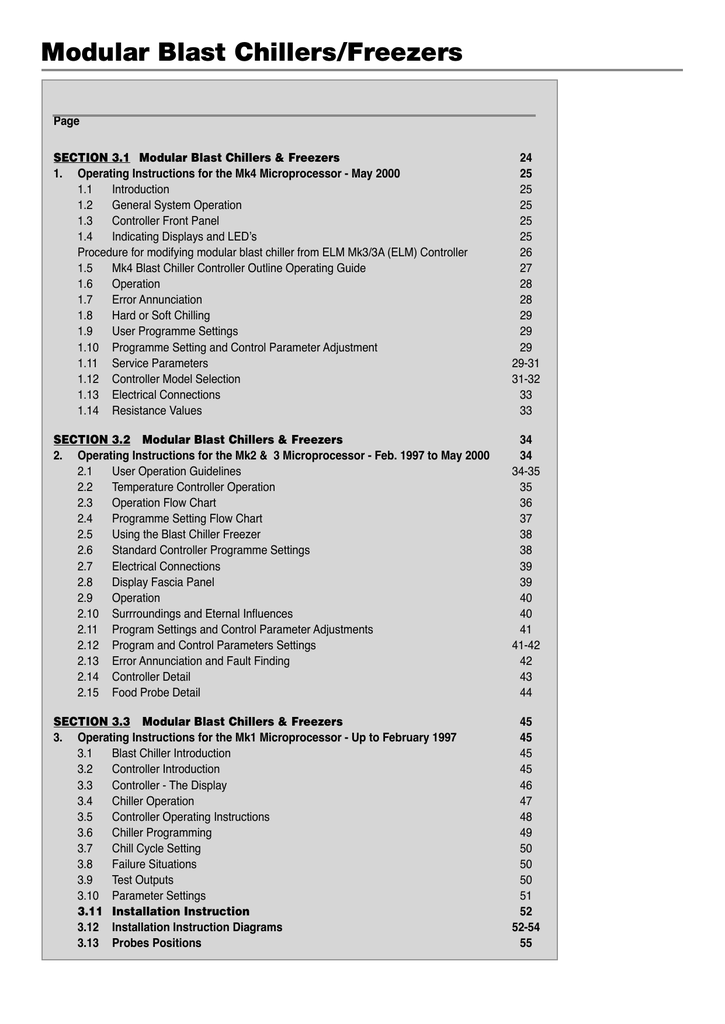

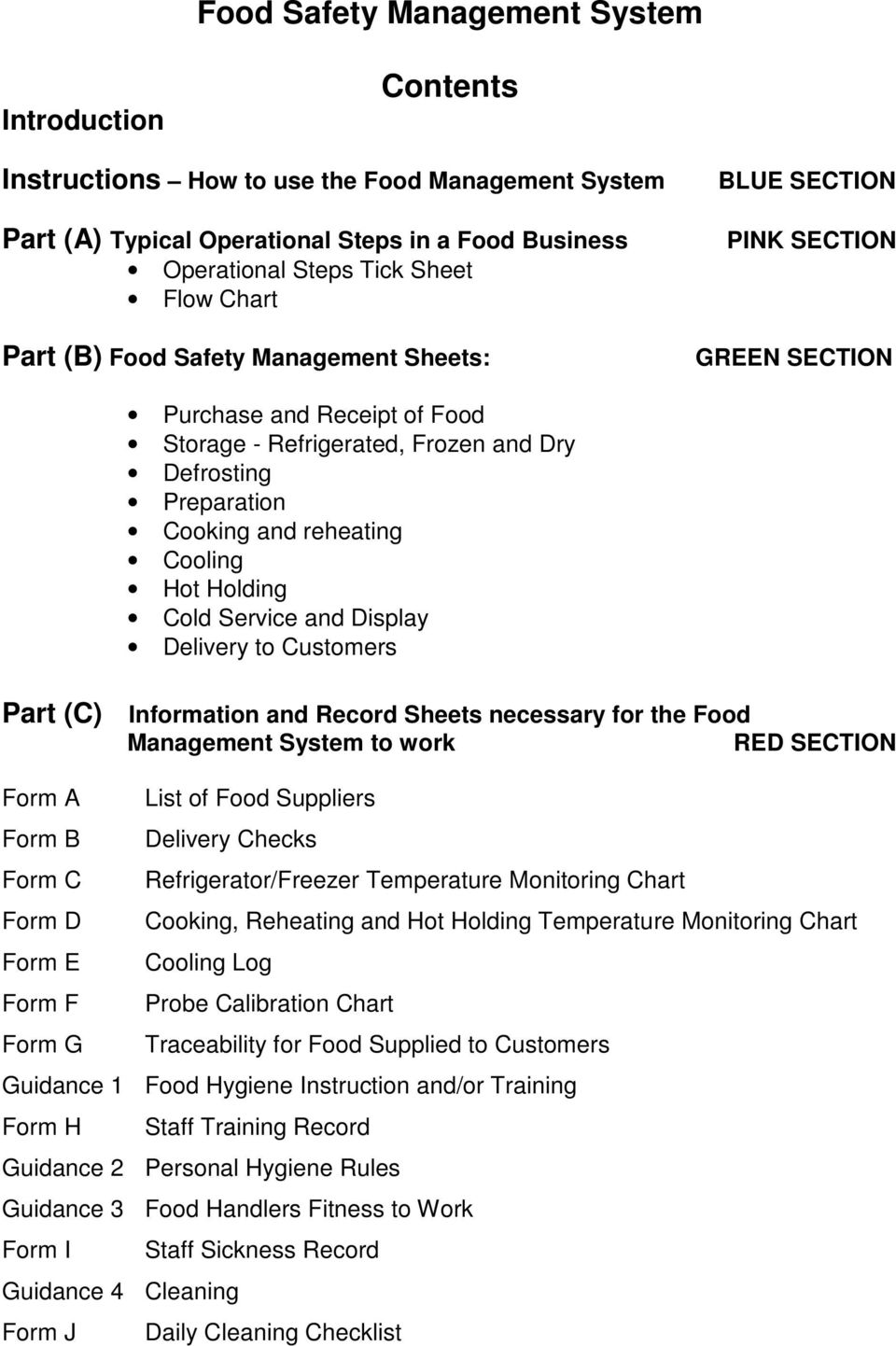

All blast chiller makers claim their equipment will bring product temperature down to a safe 41°F or less in about 90 minutes Pay close attention, though, when setting specs Some units’ claims are based on a starting temperature of 140°F, the minimum hot holding temperature in most health jurisdictions. Safe Catering Pack A User Friendly Approach to HACCP What is the Safe Catering Pack The Safe Catering Pack is a tool to help caterers develop a system to manage food safety and comply with the food hygiene regulations. End of the cycle, length of the cycle, logging of the temperature of the cabinet and goods 4 MOUNTING & INSTALLATION Model XB570L is a controller for panel mounting the cut out dimensions are 150x31 mm and it has to be fixed with screws The ambient operating temperature range is from 00 to 60°C Avoid locations subject to.

Blast Shock Freezer Supplier Mobile Blast Freezer South Africa Blast Chiller Maintenance Supplier Blast Chiller Temperature Record Sheet Plasma Blast Freezer Supplier 944% Response Rate Contact Supplier Favorites Compare 3 YRS Tianjin Hitrees Machinery Equipment Co, Ltd. The correct temperature, ie 8°C or colder for chilled food (best at 25°C) and 18°C or colder for frozen food You must record the delivery temperatures so that you can show that the food was delivered at the correct temperatures To avoid puncturing packaging you should take a temperature between packs or using an infrared thermometer. Product temperatures verified and recorded at the start of the next shift If a blast chiller is an option, the procedures above may not apply;.

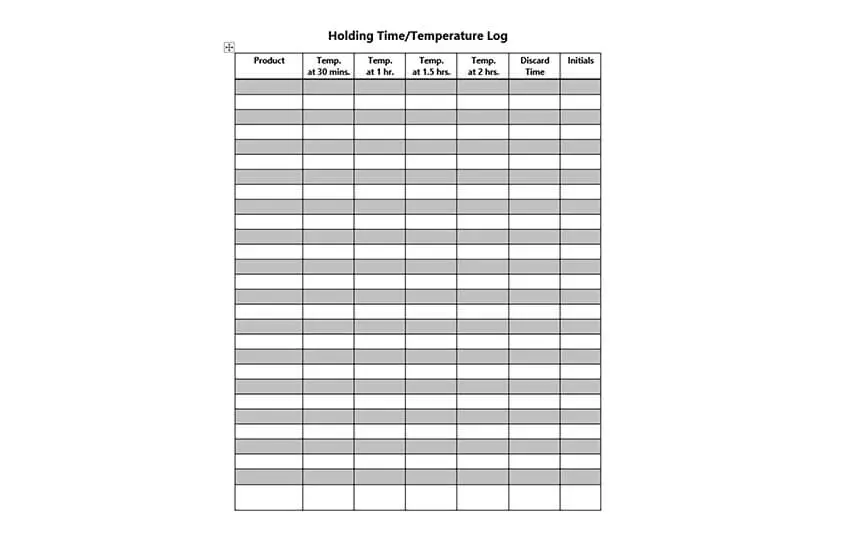

Record the time and temperature of food item Record location/method if different from above 6 Continue to monitor and record food for proper cooling time and temperature each hour At 70°F, the food should cool down to 41°F within 4 hours Cooling Time/Temperature Date Food Item/ Identifying Mark Start Time/Temp Time/Temp food item reached. In our temperature record sheet templates, we’ve included three sections for logging temperatures You’ll write the time of the check and what temperature the fridge or freezer is in each box It’s up to you whether you want to use one or all three You may even decide that the number of checks you carry out depends on the day. Temperature Records display, units (and possibly the function of your freezer/s) SC3 – Cooking/Cooling/Reheating Records To record cooking, cooling and reheating temperatures SC4 – Hot Hold/Display Records To record hot holding temperatures SC5 – Hygiene Inspection Checklist To record your own checks of your premises SC6.

That the time and temperature requirements are met Instructions 1 Record the date and food item in the columns indicated 2 Take the temperature of the food item and record the temperature and time in the column indicated If greater than 135°F, continue to monitor food until temperature reaches 135°F 3 Record time when food item reaches 135°F. • Check the core temperature with a core probe If the heart temperature set point is reached, stop cooling • Complete the blast chilling tracking sheet If the temperature and time parameters are correct, immediately store preparations in positive cold room / storage system at 3 ° C maximum (DLC D 3) Remember to. Refrigerator temperatures 40˚F/4˚C or below monitored and recorded daily;.

• In order to record any temperature on any log, a properly calibrated thermometer is needed Make sure that the method of cooling, if accelerated such as an ice bath or blast chiller, is. Equipped Blast Chiller Models 50 lb Capacity Undercounter Models j5 Over Temperature 12 j6 Product Detected 12 j7 Air Temp Sensor Not Reading 12 j8 Record Printer Media 12 j9 Label Printer Media 12 V CONTROL COMPONENTS 13 aCOMPONENT IDENTIFICATION & OPERATION 13. Blast Chiller Smart Chill RecordLabel Printers Service Manual (Smart Chill) Blast Chiller Training Guide (RBC50, RBC100, RBC0, RBC0RT, RBC400 & RBC400RT) G Series Freezer Service Manual.

With Randell blast chillers, operators enjoy enhanced product quality, highvolume production accuracy, increased savings and — most importantly — improved food safety This category of commercial foodservice equipment is engineered to sense product temperature through a standard food probe. To record HACCP reviews maximum temperature of highrisk food in a fridge is 8ºC Foods cooked and cooled without a blast chiller Day of cook plus 2 Foods cooked and cooled with a blast chiller Day of cook plus 3 Cooked foods that are vacuum packed Day of cook plus 4. The correct temperature, ie 8°C or colder for chilled food (best at 25°C) and 18°C or colder for frozen food You must record the delivery temperatures so that you can show that the food was delivered at the correct temperatures To avoid puncturing packaging you should take a temperature between packs or using an infrared thermometer.

Blast chiller to be provided with stainless steel construction and polyurethane foamedinplace insulation Blast chiller will feature high velocity forced air convection through evaporator coil Probes with sequential readout display will be supplied for food temperature recording (four probes in MCR model, eight in MCR). Mometer for blast chiller ambient air temperature (requires printer to have record) • 3 food temperature probes with sequential readout display in MCR, 6 probes in MCR • Automatic chill cycle control with food temperature probes DOORS • Door dimensions 30" x 78" • Flush mounted • 36" high 16 ga stainless steel kick. Safe Catering Pack A User Friendly Approach to HACCP What is the Safe Catering Pack The Safe Catering Pack is a tool to help caterers develop a system to manage food safety and comply with the food hygiene regulations.

This record book should be used for recording temperatures of food cooked on your premises If the food is cooled, the time it is placed into the fridge/blast chill/blast freezer should also be recorded If the food is reheated, the date and the reheating temperature should also be recorded. Mometer for blast chiller ambient air temperature (requires printer to have record) • 3 food temperature probes with sequential readout display in MCR, 6 probes in MCR • Automatic chill cycle control with food temperature probes DOORS • Door dimensions 30" x 78" • Flush mounted • 36" high 16 ga stainless steel kick. The Blast Chill Process All Models 1) While in a blast chill cycle, cold air is rapidly being circulated around the food pans in order to remove heat as rapidly as possible 2) Actual chill times will vary depending on many product related factors such as starting temperature, product density, cycle load, content, etc.

Once the temperature probe is in place, Traulsen Blast Chillers can begin chilling cooked food to safe storage temperatures Menu presets offer customization and flexibility for a large variety of foods, and the auto start mode chills multiple batches without any staff input, while. Food temperature recording (four probes in MCR model, eight in MCR) An automatic chill cycle control with food temperature probes is also supplied A thermometer will be provided for recording blast chiller ambient air temperature Thermometer will require optional printer for record of temperatures Rollin blast chillers will con. Records should be kept on the record sheet entitled Form 37 Chilling foods in a blast chiller is the preferred method spread the food out on shallow, metal trays and ensure the door is not.

Blast chillers report temperatures automatically and keep your records for you Blast chillers are designed to bring the core temperature of food from around 160°F or more down to 41°F or less in about 90 minutes Most units will freeze food in four hours or less Cutting the time needed to cool food by 75% is a great benefit to any operation. To record HACCP reviews maximum temperature of highrisk food in a fridge is 8ºC Foods cooked and cooled without a blast chiller Day of cook plus 2 Foods cooked and cooled with a blast chiller Day of cook plus 3 Cooked foods that are vacuum packed Day of cook plus 4. The Victory Blast Chiller is designed to reduce the temperature of 2" thick, uncovered food from 160°F to 38°F in approximately 90 minutes.

Blast Chiller Model APBCF03 is used to rapidly chill cooked foods to temperatures suitable for refrigerated storage It is capable of lowering the core temperature of up to 0 pounds of most. 3 Check temperature of incoming meat products (2 boxes/load) Record temperatures on incoming meat invoices Reject meat products that are more than 50oF or evaluate product and cool rapidly 4 Product is to be placed in cooler or freezer immediately on racks approved for specific products 5. 3 Check temperature of incoming meat products (2 boxes/load) Record temperatures on incoming meat invoices Reject meat products that are more than 50oF or evaluate product and cool rapidly 4 Product is to be placed in cooler or freezer immediately on racks approved for specific products 5.

When using a blast chiller food must be initially cooked to 75°C for 30 seconds portioned into shallow containers without delay cooled to 5°C within 90 minutes using the blast chiller cooking, and cooling temperature and times must be recorded on the SMS_FS_GU_023a_Cooking Times & Core Temperature Record_V1.

Checklist For The Blast Freezer System

Blast Chillers Cw Blast Chiller Crosswise 56 Kg R452a 1101 Zanussi Professional

Haccp Manual

Blast Chiller Temperature Record Sheet のギャラリー

Haccp For The Hospitality Industry A Psychological Model For Success Emerald Insight

Blast Chiller Controller Xb590l Manualzz

Standard Operating Procedure Index Food Hygiene Safety

2

Haccp Manual

Blast Chiller Freezers Opulentng Com

Warwick Ac Uk Services Healthsafetywellbeing Guidance Foodhygieneandsafety Manual2 Operationalstandards Os12 Blast Chilling Of Food V3 Pdf

Temperature Log Sheets For Busy Kitchens Free Templates

Safe Cater Section 4 Refrigerator Hygiene

Blast Chillers Market Industry Analysis And Forecast 19 27

Electrolux Rbf051 Benutzerhandbuch Seite 1 Von 5 Manualsbrain Com

Safe Catering 5 Recording Forms

Electronic Blast Chiller And Freezer Mod Alexander 2 3 Air Cooled Rack Capacity N 2 X Gn 2 3 Cm 35 4 X 32 5 Core Probe Chilling 70 3 Kg 8 Freezing 70 18 Kg 3 Dimensions Cm L 68 X D 54 X H 52 Ec Standards Allforfood

Haccp Manual

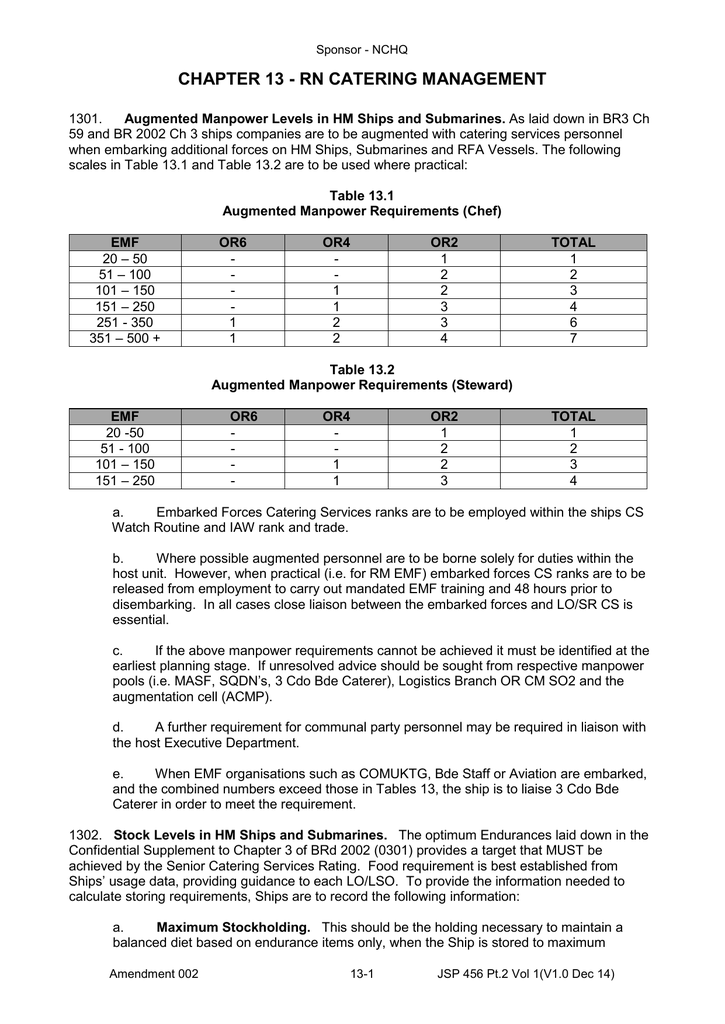

Royal Navy Catering Management Manualzz

Electrolux Air O Chill Brochure Specs Pdf Download Manualslib

Haccp Plan

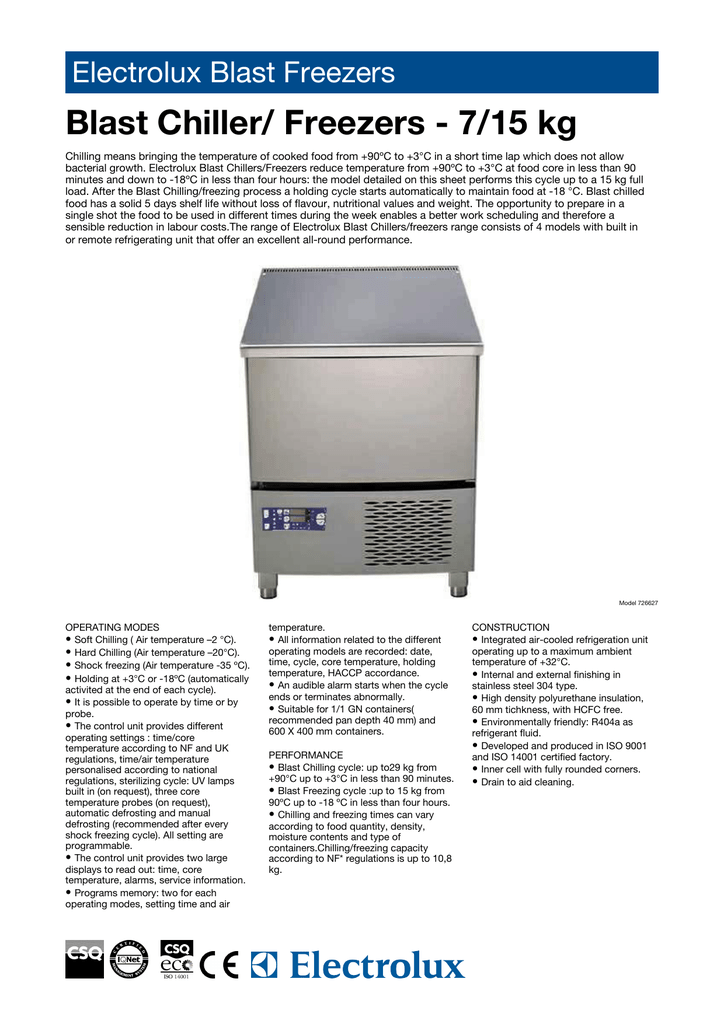

Electrolux Blast Freezers Manualzz

Internet Of Things Linked Wearable Devices For Managing Food Safety In The Healthcare Sector Sciencedirect

2

Www Food Gov Uk Sites Default Files Media Document Sfbb Caterers Pack Pdf

Victory Vbc 75 Specifications Pdf Download Manualslib

Future Plus Dc730 Light Duty Blast Chiller Porkka Belgium

Electrolux Professional Air O Chill Freezer

Electrolux Aofp101c Technical Data Pdf Download Manualslib

Temperature Log Book Products For Sale Ebay

Why And How To Use A Blast Chiller Hengel

Electrolux Air O Chill Aofp061c Specifications Pdf Download Manualslib

Electrolux Air O Chill User Manual 4 Pages Also For Air O Chill

Food Safety Management System For Pdf Free Download

Electrolux Crosswise Blast Chiller Freezer 11 Tray 11 X 1 1gn Rbf101 Popular Accessories Electrolux Refrigeration Rac52 Crosswise Blast Chiller And Freezer Accessory Unavailable Features Designed Solely For Rapid Reduction In Food Temperature The

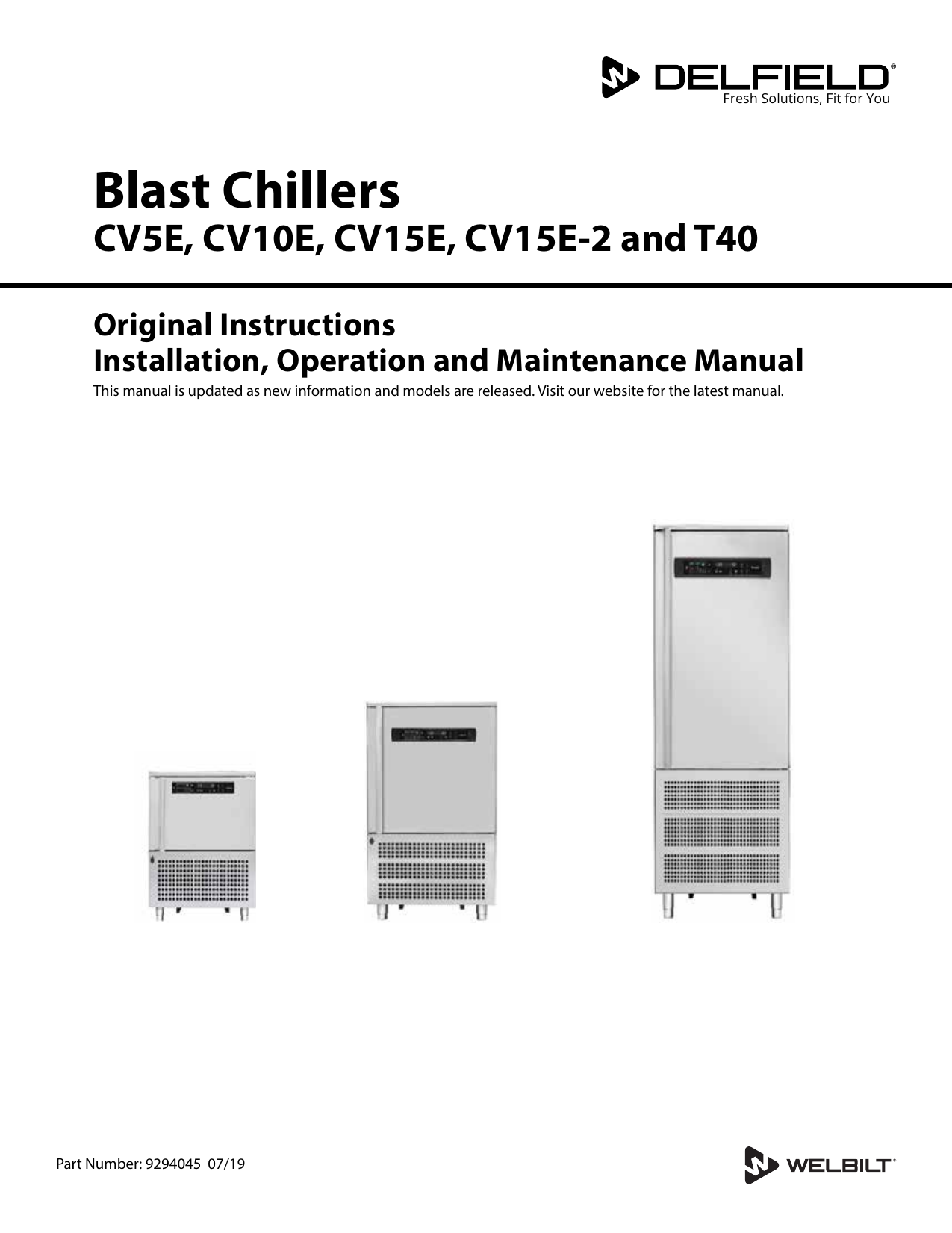

Delfield Cv15e 32 Self Contained Blast Chiller Shock Freezer 143 Lb 110 Lb

Ed Sc Gov Districts Schools Nutrition Wellness And Food Safety Food Safety Hazard Analysis Critical Control Point Haccp Binder 2 Haccp Plan 2 6 Monitoring And Recordkeeping

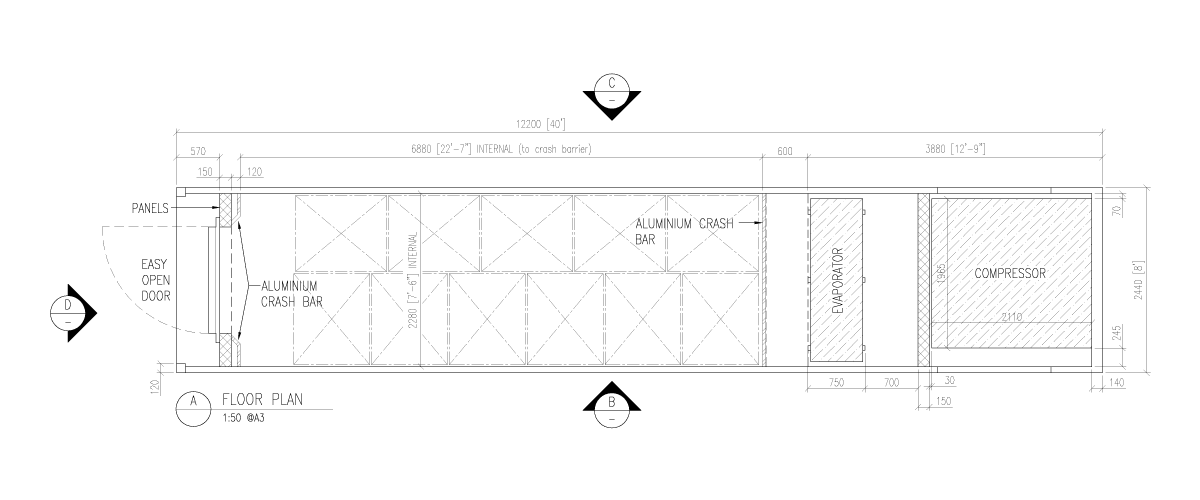

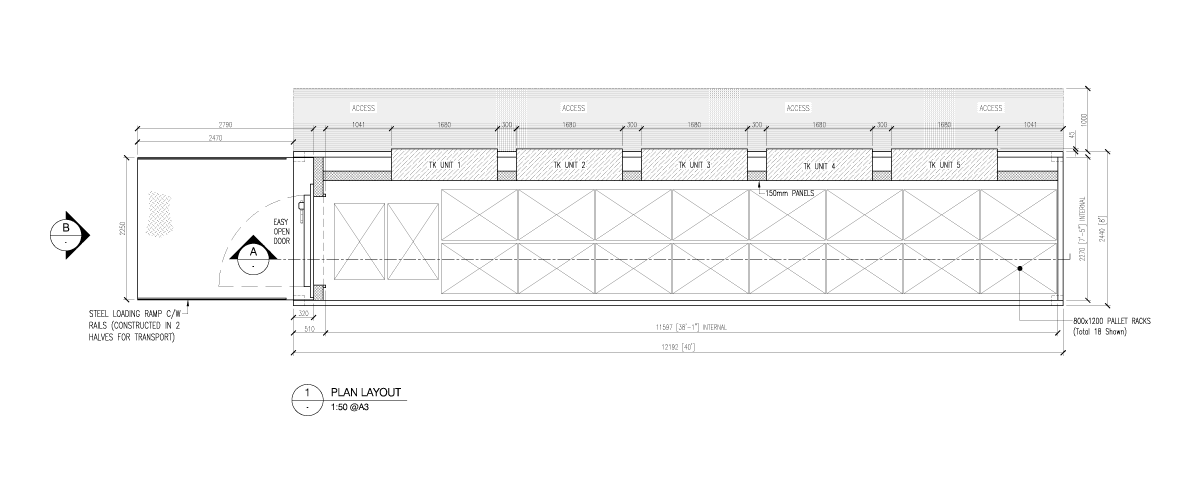

40ft Iso Blast Freezer For Fast Accurate Freezing Crs

Www Food Gov Uk Sites Default Files Media Document Sfbb Caterers Pack 1 Pdf

Time To Chill With Blast Chillers Foodservice Equipment Reports Articles News Fer Magazine

Www Hsdl Org View Did

Blast Chiller Shock Freezer Reach In Self Contained Standard Manualzz

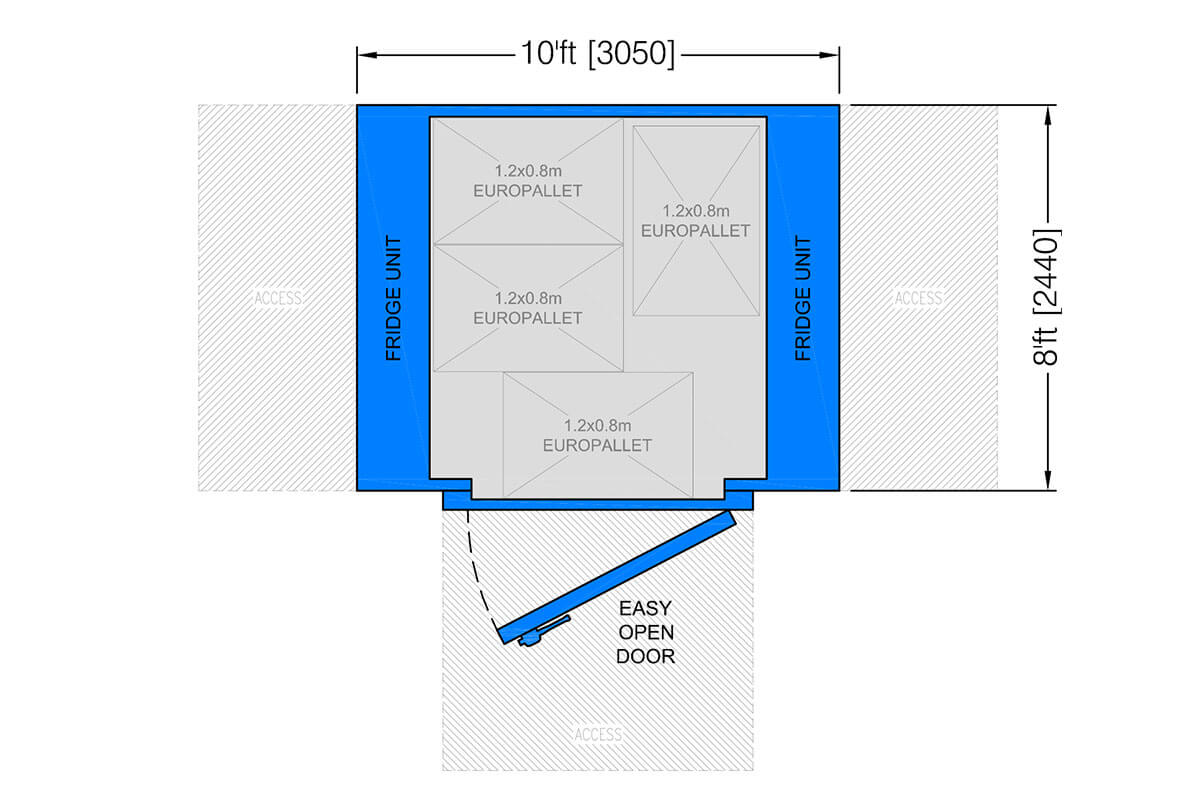

10ft Blast Freezer Powerful Compact Ideal For All Industries Crs

Assets Centralrestaurant Com Pdfs Specsheets 955 0 Pdf

Safe Ways To Cool Food Contra Costa Health Services

2

Electrolux Blast Freezers Rbf061r Hdba010

The In Depth Blast Chiller And Freezer Buying Guide Ffd Ltd

Www Afinox Com Wp Content Uploads 18 02 00 En Pdf

Blast Masters Latest Blast Chilling Solutions Provide Operators With A Rapid Route To Menu Maximisation

180 Kg Air O Chill Blast Chiller Freezer 2 Pass Electrolux

Time To Chill With Blast Chillers Foodservice Equipment Reports Articles News Fer Magazine

Future Df7 Light Duty Blast Freezer Porkka Central Europe

Boh Stock Control Tcbsopsite

Electrolux Rbf051 Benutzerhandbuch Seite 1 Von 5 Manualsbrain Com

Foster Blast Chiller Service Manual

Pdf Case Studies In Food Freezing At Very Low Temperature

Electrolux Blast Chillers

Time To Chill With Blast Chillers Foodservice Equipment Reports Articles News Fer Magazine

Blast Chillers Market Industry Analysis And Forecast 19 27 By Type Application Chilling And By Maximize1 Issuu

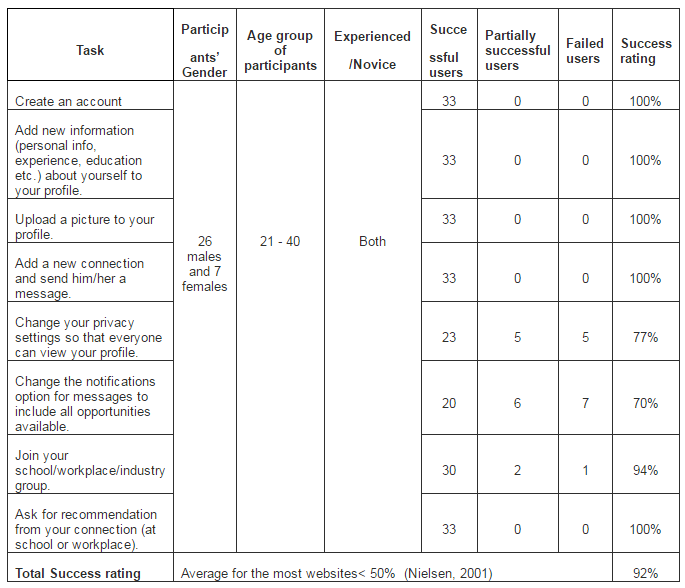

Ibima Publishing Improving Usability Of Social Networking Systems A Case Study Of Linkedin

Blast Chillers And Freezers Lw Blast Chiller Freezer 2 1 Manualzz

Refrigeration Load Sizing For Walk In Coolers Freezers Other Boxes Industrial Controls

Hse Guidelines For Maintaining The Vaccine Cold Chain Including Maintenance Of Vaccine Fridges And Management Of Vaccines Pdf Free Download

Safe Cater Section 4 Refrigerator Hygiene

Electrolux Rbc101 Users Manual Blast Chillers

5 Randell Pdf Catalogs Documentation Brochures

Irinox Blast Chiller Shock Freezer Reach In Mf 25 1 Kc Foodservice

Www Sagispa It En Download Ipat 6 Partnum Ifr1r Path Libretti Filename Gb Pdf

Ag 15 Iglu Cold Systems Australia Manualzz

Www New Ox Ac Uk Sites Default Files 19 10 Food safety policy oct 019 Pdf

Time To Chill With Blast Chillers Foodservice Equipment Reports Articles News Fer Magazine

Knowledge Base

Www Tararuadc Govt Nz Files Assets Public Pdf Publications Forms Amp Information Environmental Health Food Amp Health Licensing Food Control Plan Pdf

Iglu Blast Chiller Shock Freezer 5 Tray Iglu Cold Systems Australia

Www New Ox Ac Uk Sites Www New Ox Ac Uk Files 18 04 Food safety policy february 18 Pdf

Safe Food Hygiene Standards Ppt Download

Electrolux 7266 Brochure Specs Pdf Download Manualslib

Theicn Org Resources 521 Food Safety Fact Sheets Holding Cold Foods Pdf

Electrolux Rbf051 Benutzerhandbuch Seite 1 Von 5 Manualsbrain Com

Safe Catering 5 Recording Forms

Boh Stock Control Tcbsopsite

Iglu Blast Chiller Shock Freezer Tray Iglu Cold Systems Australia

Electrolux Aof28crd Technical Data Pdf Download Manualslib

Blast Chillers Freezers Cw Blast Chiller Freezer Crosswise 64 Kg Electrolux Professional Middle East

Blast Chillers Cw Blast Chiller Crosswise 10 Kg Electrolux Professional

Www2 Health Vic Gov Au Api Downloadmedia 7bc1a6b010 7fc7 45ce A68b 8046df 7d

Safe Food Hygiene Standards Ppt Download

Time And Temperature Control Tcs Foods Full Guide Thermopro

Www Food Gov Uk Sites Default Files Media Document Sfbb Caterers Pack 1 Pdf

40ft Blast Freezer Fast Effective Cooling With A Huge Capacity Crs

Pdf Cooling Meat Products In Foodservice Time Temperature And Growth Of Clostridium Perfringens Atcc 103

Food Safety Management System For Pdf Free Download

Polar Dn494 Specification Sheet Manualzz

Knowledge Base

Electrolux Blast Freezers Rbf061r Hdba010

A Guide To Choosing Blast Chillers Blog Ckitchen Com

Delfield Cv Blast Chiller Iom T5 T14d T40 Convochill Blast Chiller User Manual Manualzz

Www Mpi Govt Nz Dmsdocument Direct

Beverage Air Wbc75 35 1 2 Floor Model Reach In Blast Chiller 12 Pan Capacity 8v 1ph

5 Randell Pdf Catalogs Documentation Brochures