Doctor Blade Coating Method

Doctor and roll cleaning blades are used to clean rolls and remove stock accumulations, water, pitch, and filler buildup With thousands of installations around the globe, our doctoring and roll cleaning technologies offer highperformance cleaning and water removal in a variety of roll cleaning and scraping applications.

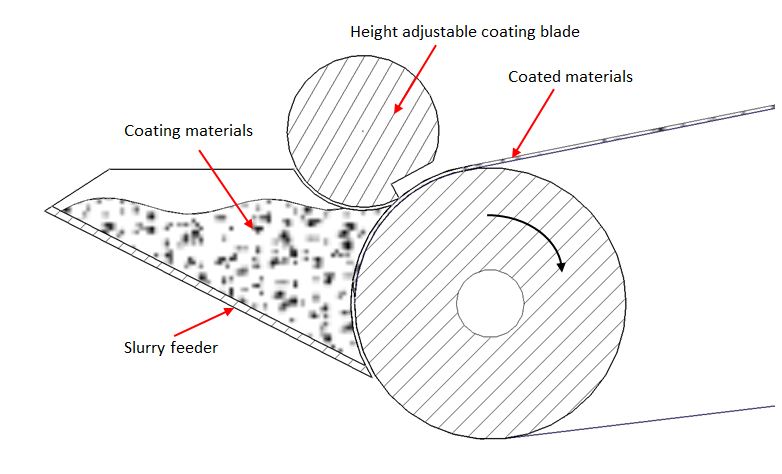

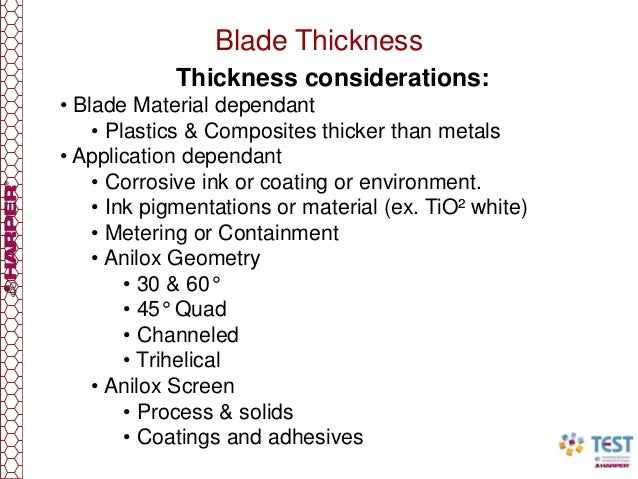

Doctor blade coating method. Doctor Blade Coating Machine for Battery Electrode Coating MDTMJ0 is a compact tape casting coater with a heating cover designed to produce films with consistent thickness It has a unique driving system to produce smooth coating on all types of materials. The automated system for operating a chambered doctor blade assembly of claim 11, wherein said electronic control means is programmed to run a nonwaterbased coating through said doctor blade assembly, and thereafter to drain the nonwaterbased coating and wash the system with solvent without necessitating removing said doctor blade assembly. In printing the doctor blade removes the excess ink from the smooth nonengraved portions of the anilox roll and the land areas of the cell walls Doctor blades are also used in other printing and coating processes, such as flexo and pad printing for the same function It is believed that the name derives from the blades used in flatbed letterpress equipment for blades used to wipe ductor rolls, and "ductor" became doctor A technician installs a doctor blade for flexographic printing.

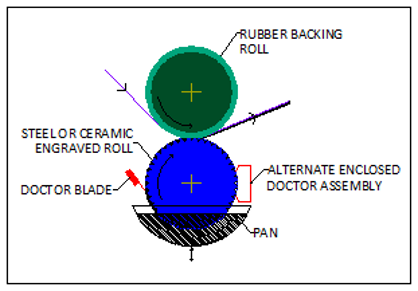

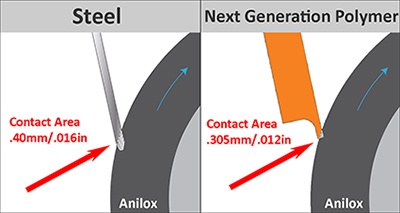

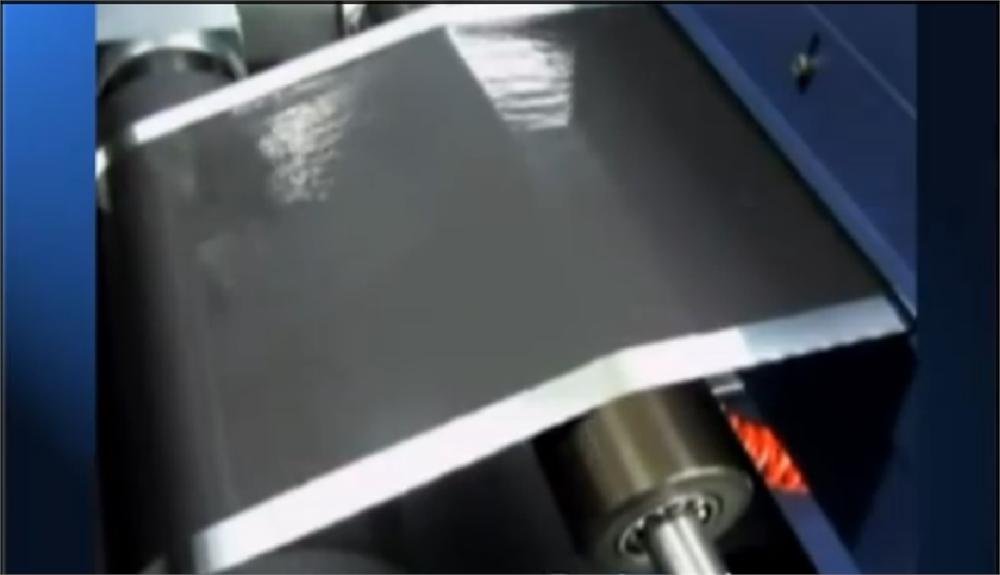

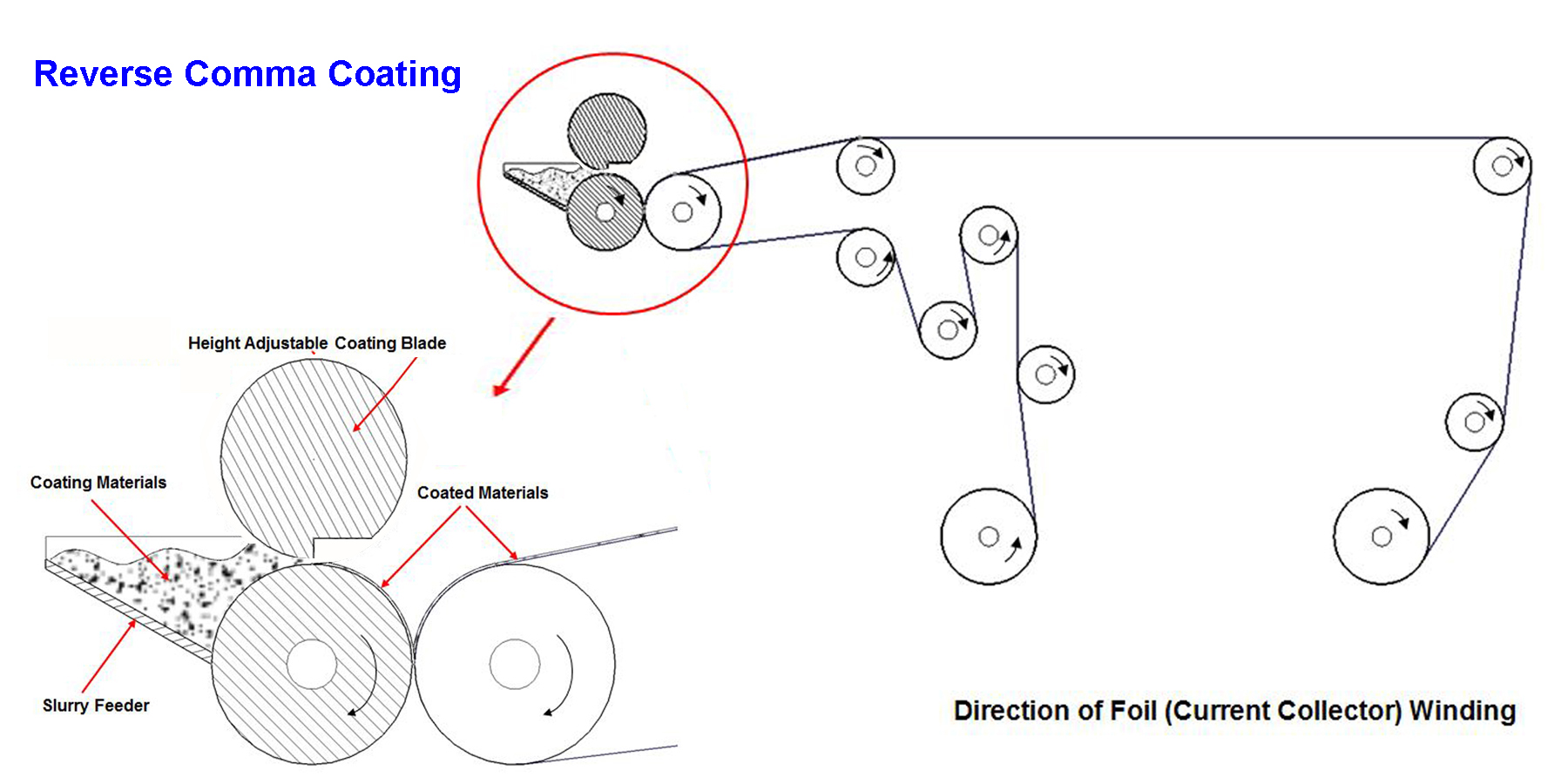

The coating applicator is either an enclosed chamber with two doctor blades to an open pan with a doctor blade assembly to remove the excess coating In this method all the rolls are turning in the same direction at the point of contact at each nip. Carbon films prepared by doctorblade coating method have been reported as the top electrode in HPSCs The efficiencies of these devices suffer from the poor interface between the doctorblade coated carbon and the underlying perovskite layer. Doctor blade manufacturers have found a way to make new polymer doctor blade materials that can overcome the limitations of steel in specialty coating applications By engineering a modified lamella tip, known as a “MicroTip”, on these materials, they have introduced a doctor blade product that offers the best of traditional plastic and steel.

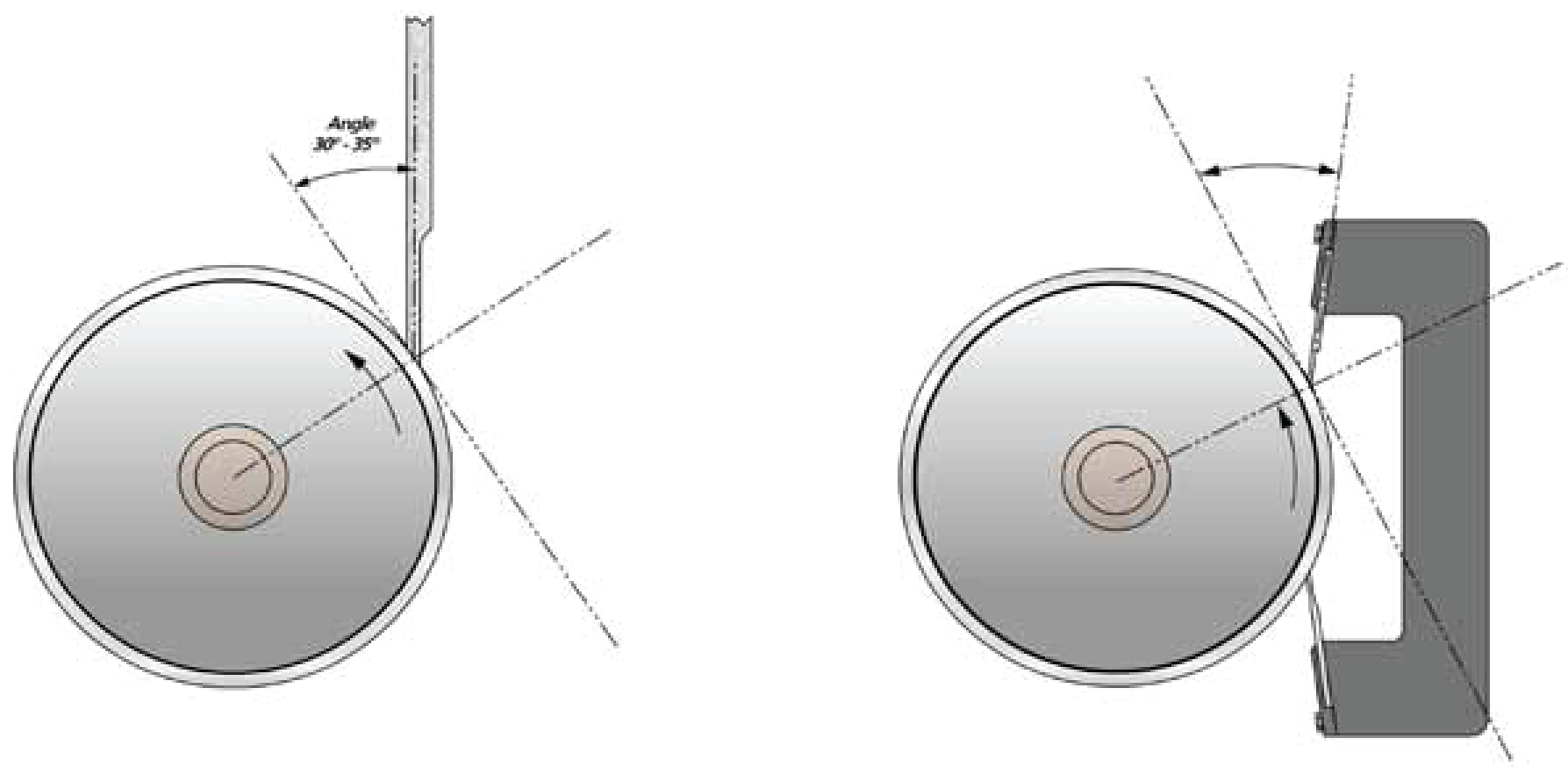

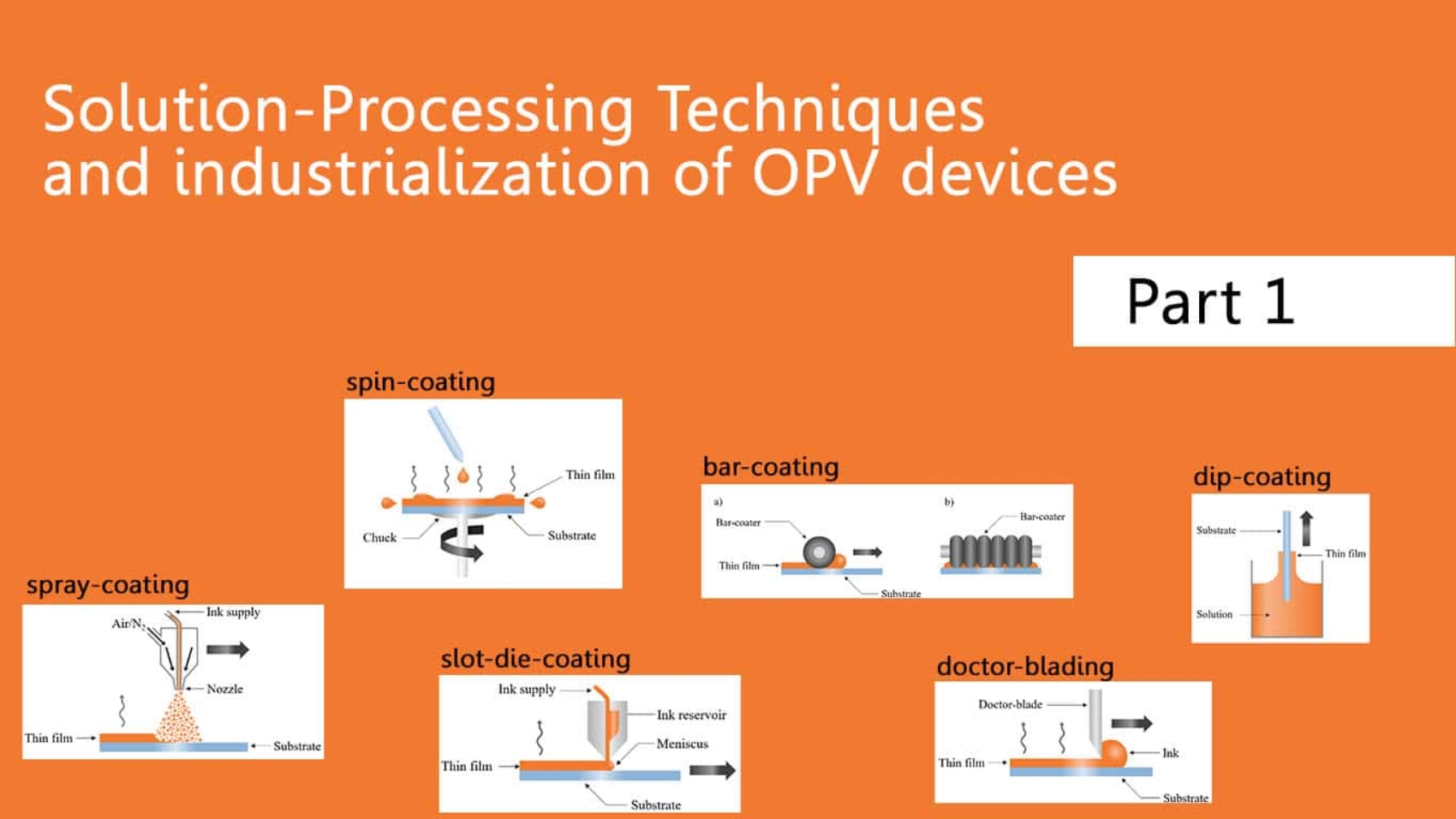

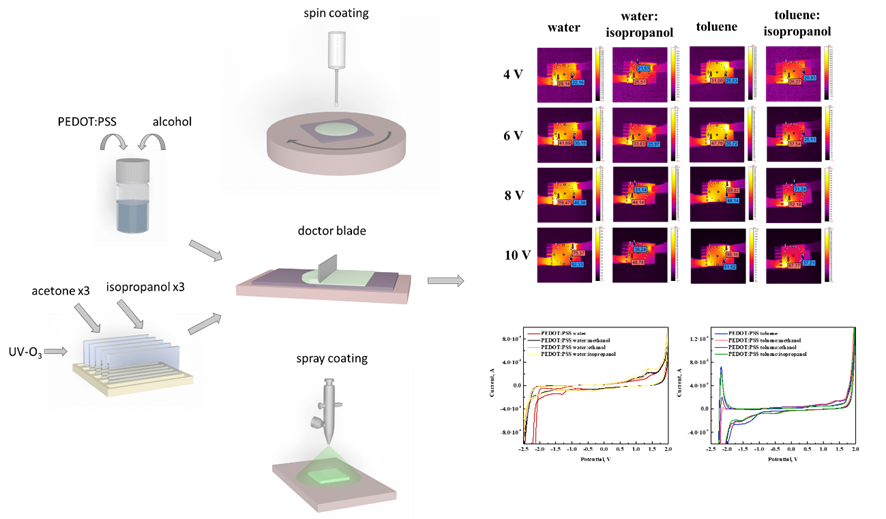

A doctor blade that’s installed correctly will have uniform, balanced contact with the anilox roll and remove ink consistently across its surface Blade positioning, orientation, angle and pressure will affect the delivery of a precise amount of ink to the plate, and proper installation will give the printer control over consistent, repeatable print quality. Doctor Blades are extremely smooth lamella and non lamella ( round edge) blades and used for wiping out the excess ink in flexographic or rotogravure printing and coating processes They are also used for printing and coating on paper, films sch as PET, BOPP, PVC and foils used in packaging labeling, publication & corrugation industries. Thus, in this study, we have further compared the BHJ and LbL processing strategies via the doctorblade coating technology because it is a rolltoroll compatible highthroughput thin film fabrication route We systematically evaluated multiple target parameters, including morphological characteristics, optical simulation, physical kinetics.

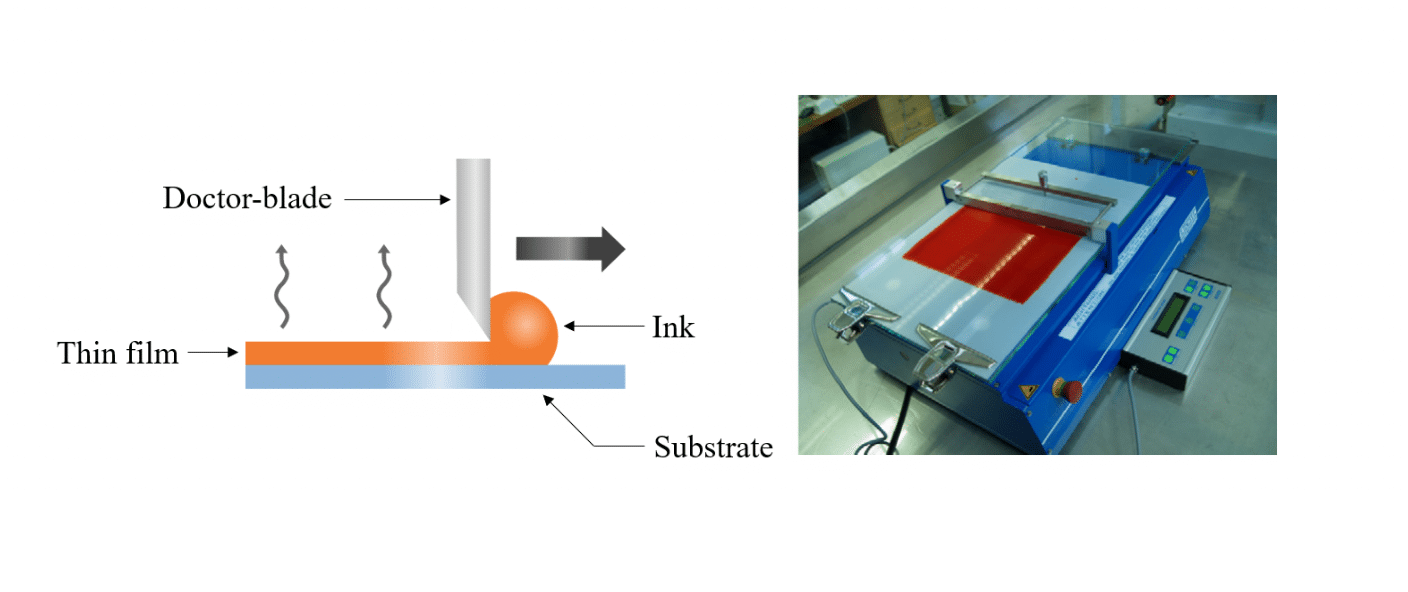

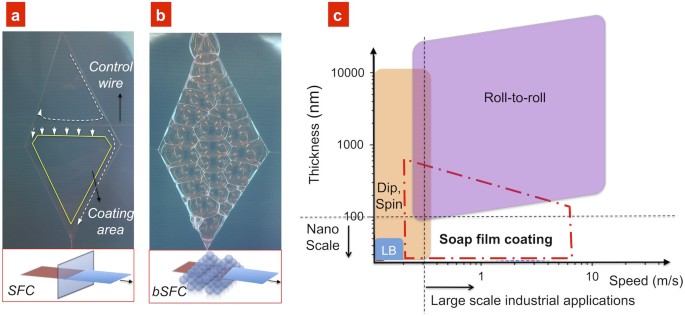

Coating fluid is pooled between the applicator roll and the substrate, and the blade on the roll wipes off excessive fluid to ensure an optimum coating thickness This method is generally suited for highly viscous coating fluids or when forming a thick coating However, some models can support various coating thicknesses Examples of other methods. Swedish steel has exceptionally high quality We can completely rely on its strength, which makes it possible for us to deliver precision made, highclass products under the SWED/CUT® brand year after year Swedev has developed a patented surface coating method in cooperation with highly demanding printers The coating reduces frictionRead More. Rolltoroll coating under clean room conditions (ISO 100 000) Dip coating (up to a size of 1 m) Milling (flexible and solid substrates) Spinning;.

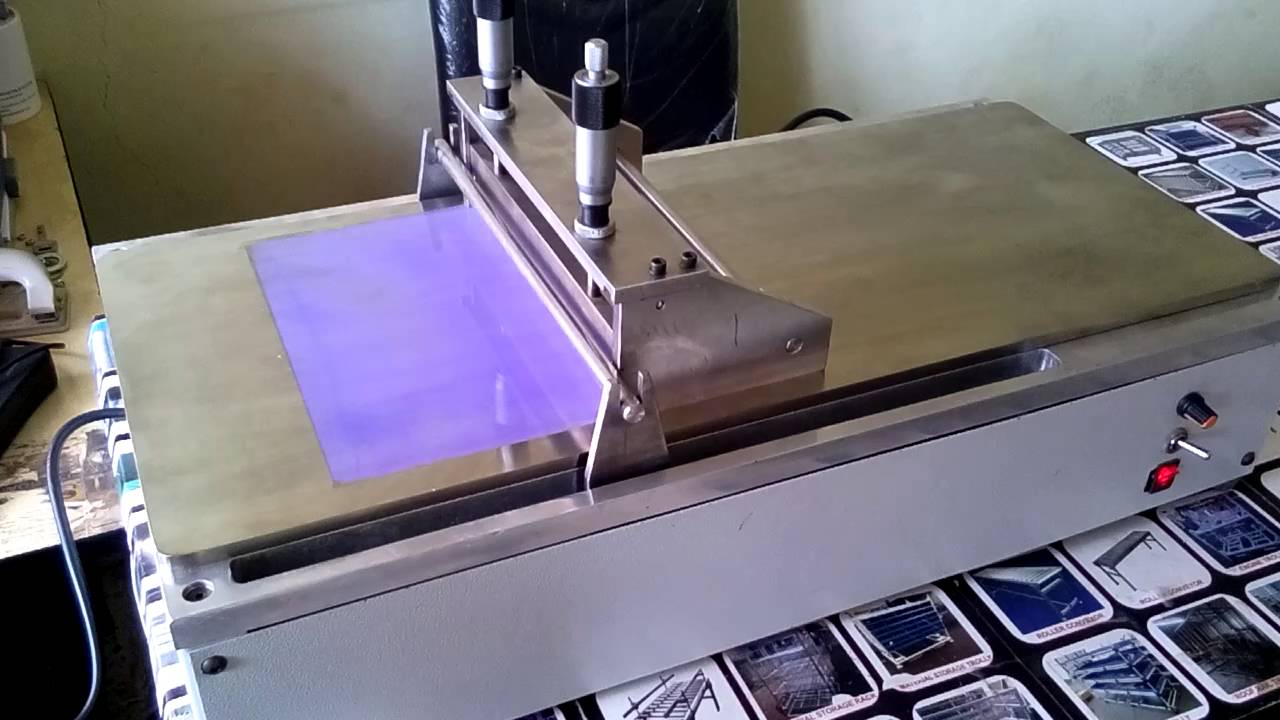

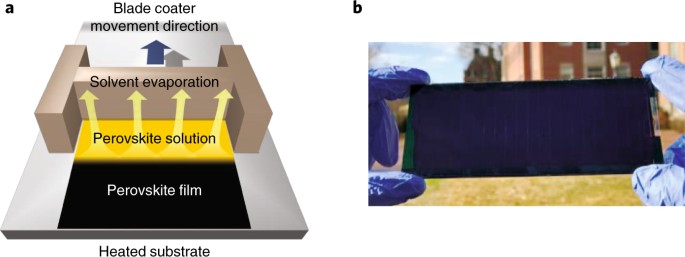

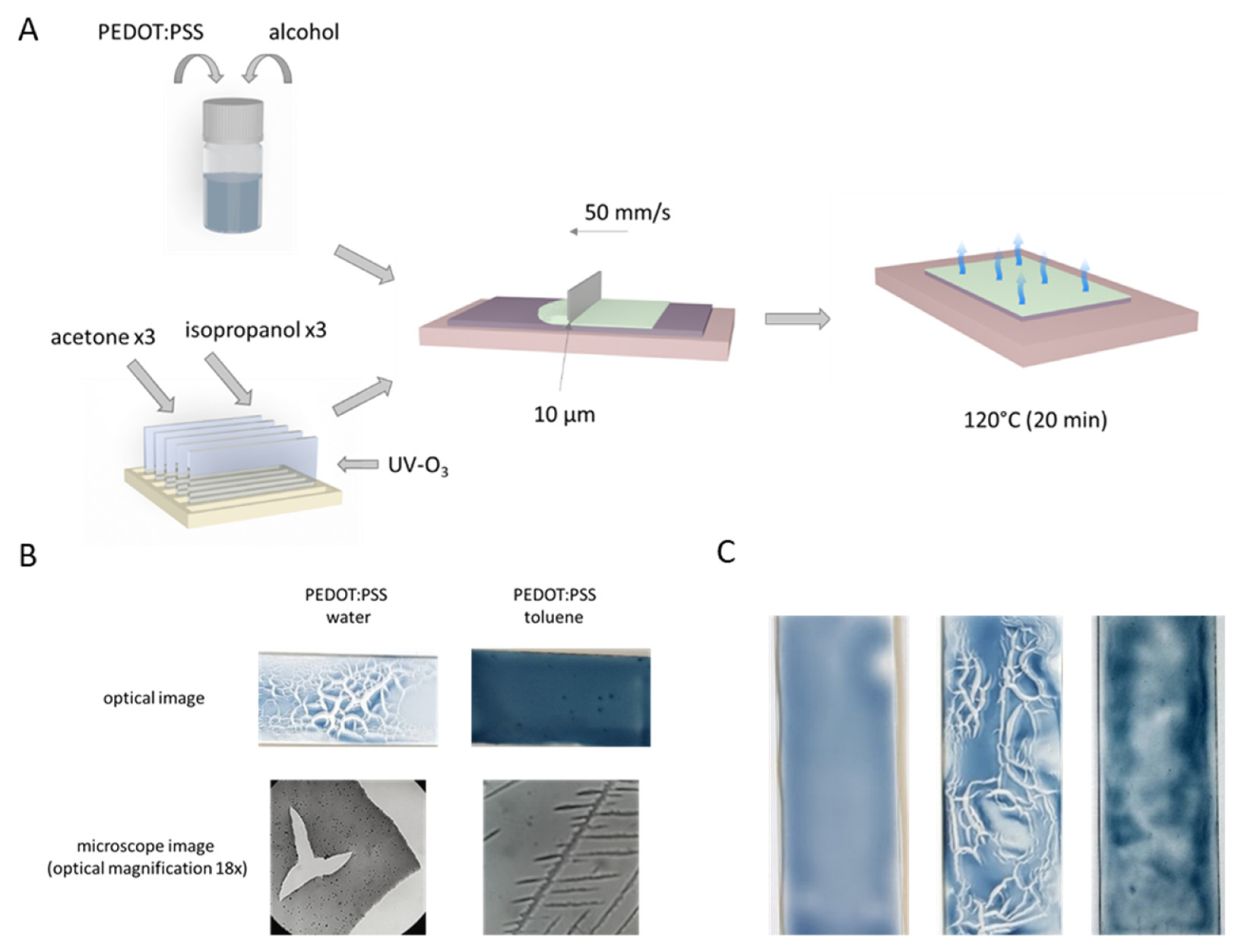

Improperly used, either mode of doctoring can result in coating carry over due to blade flexure Enclosed, chambered coating applicators feature a combination of powered coating feed and doctor blade metering Coating compound is pumped through the chamber enclosure, via ports designed to optimize the coating distribution Doctor blades are placed at the top and bottom of the applicator, affording total enclosure control of the system. Blade coating method Broader context Doctorblade coating is a scalable, simple, lowcost, low temperature, solution based thin film deposition technique that is compatible with rolltoroll fabrication of large area devices with a high throughput Here we show that the large area (1 in 1 in) organolead trihalide perovskite (OTP) solar cells. Doctor Blade Coating Machine for Battery Electrode Coating MDTMJ0 is a compact tape casting coater with a heating cover designed to produce films with consistent thickness It has a unique driving system to produce smooth coating on all types of materials The flat vacuum chuck is built in to hold substrate sheet in place, which is particularly useful when making thin coatings.

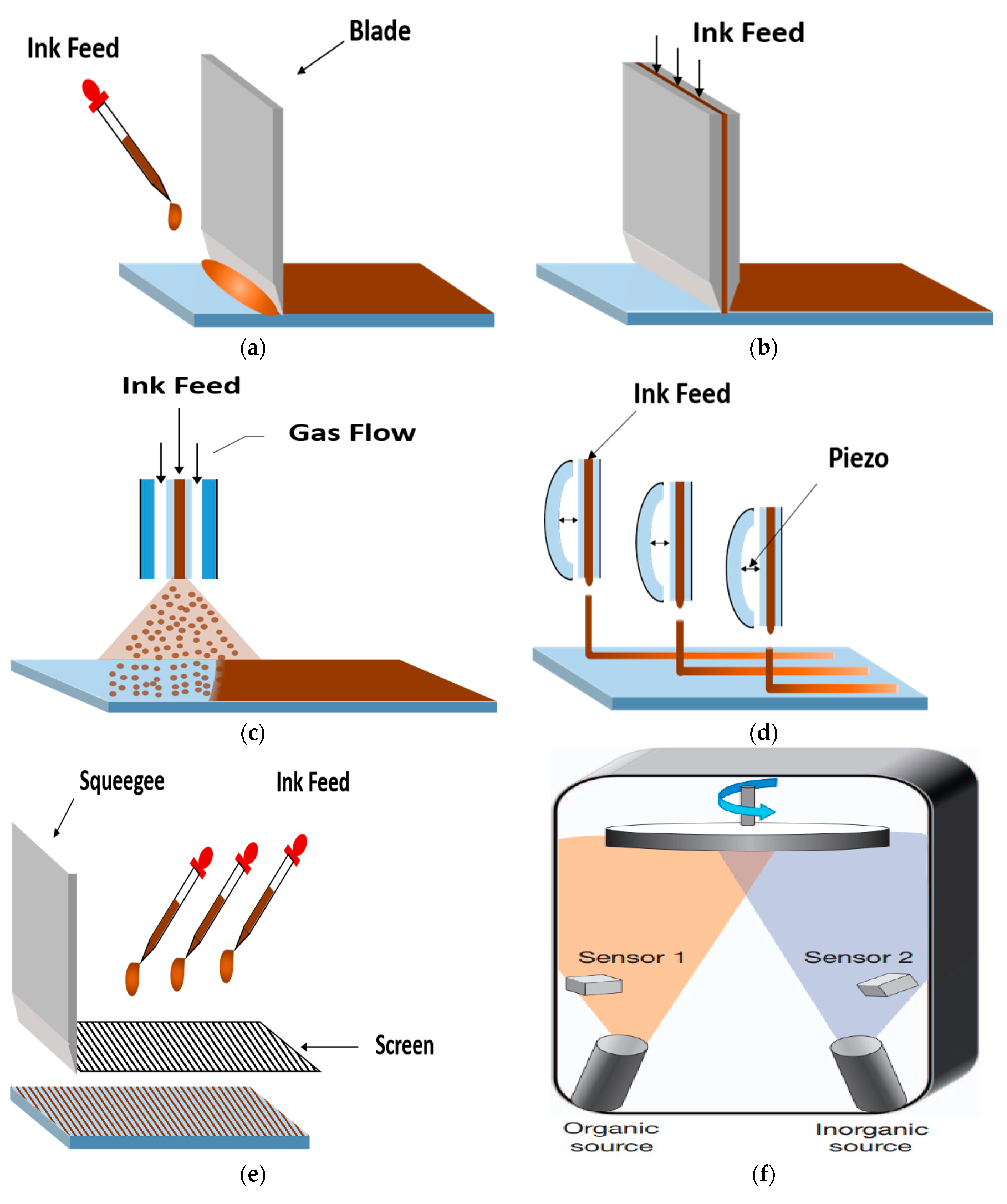

The current work reports the fabrication of fully coated inverted organic solar cells by combining doctorblade coating and spray coating and, more importantly, demonstrates that a nanocomposite of a polyoxometalate and conjugated polymer could be an excellent anode buffer layer for the fully coated polymer solar cells with favorable. Using too much pressure on the doctor bladebecause of a mechanical issue on the press is one reason to use coated blades Using a coated blade is less likely to cause a burr and can withstand more tension than an uncoated blade If the ability to control the ink film is a result of using too much pressure on the blades, then a MDC Soft Blade. Largescale coating technologies, ie, doctorbladecoating method and slotdie coating method, which are inexpensive and easily transferable to an R2R coating environment Overall, from these reasons, to move on the crucial step for industrial application, efforts to investigate the influence of the blend microstructure and pro.

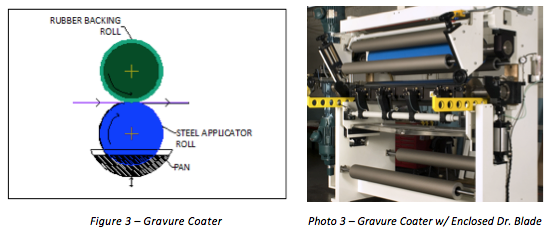

Abstract The present invention refers to a doctor blade (1) comprising a metal support (3) completely coated with a polymeric material The doctor blade (1) works in combination with a cylinder (2) and consists of a steel support (3) with a polished surface coated with a layer of variable thickness of polymeric material, comprising an ultrathin layer (0) which coats the whole surface of the doctor blade (1);. The doctor blade ( 1 ) works in combination with a cylinder ( 2 ) and consists of a steel support ( 3 ) with a polished surface coated with a layer of variable thickness of polymeric material,. The cells are usually filled with a liquid by rotating the gravure roll into a liquid pool (filling process), and the excess liquid on the roll surface is wiped off by a doctor blade (doctoring process) The liquid remaining in the cells is partly transferred to the substrate (transfer process).

The patented 900 Nano blade is produced by treating the base material to change the steel structure itself thereby eliminating the need for any coating This method increase blade life and reduces friction, and it is an environmentally friendly way of producing long life doctor blades as no toxic waste products are created. A thicker layer (6) which coats one side of one edge (4, 5) of the doctor blade (1. The blade coater rolls the liquid coating onto the bottom of the paper, then uses a flexible blade to scrape away the excess coating This method produces a sheet with high gloss, but the resultant variation in coating thickness can cause inconsistent ink holdout and produce uneven printed solids (mottle).

Doctor blading also known as knife coating or blade coating is a popular thinfilm fabrication technique It involves either running a blade over the substrate or moving a substrate underneath the blade There is a small gap that determines how much solution can get through Here, solution is effectively spread over the substrate. Doctor and roll cleaning blades are used to clean rolls and remove stock accumulations, water, pitch, and filler buildup With thousands of installations around the globe, our doctoring and roll cleaning technologies offer highperformance cleaning and water removal in a variety of roll cleaning and scraping applications. The coater or doctor blade is brought to pass as a continuous strip through at least two, in the shown embodiment three electrolytic cells 21, 22, 23 with contact polarisation of the blade 1 via anodic electrode rollers 25 It is preferred that the cells are adequately wide so that two or more blades can be coated at the same time during continuous operation.

The present invention refers to a doctor blade comprising a metal support completely coated with a polymeric material, in particular Teflon s®, and a method of coating said support Doctor blades are wellknown tools and are normally used to remove from a cylindrical surface—with a finite radius (cylinder) or an infinite radius (flat surface. In printing the doctor blade removes the excess ink from the smooth nonengraved portions of the anilox roll and the land areas of the cell walls Doctor blades are also used in other printing and coating processes, such as flexo and pad printing for the same function It is believed that the name derives from the blades used in flatbed letterpress equipment for blades used to wipe ductor rolls, and "ductor" became doctor. In addition, solution phase chemical methods such as spin coating, spray pyrolysis, electrodeposition, doctor blade, centrifugal casting, screen printing, and combustion 26, 27 have also been.

Even though the doctorblade coating technique has been widely used to prepare PSCs, it is yet to be applied to highefficiency PSCs under ambient conditions (RH∼45%, RT∼25 °C) In this study, we conducted bladecoating fabrication of modified highefficiency PSCs under such conditions. Doctor blade (or tape casting) is one of the widely used techniques for producing thin films on large area surfaces Tape casting is a relatively new process which was originally developed during the 1940’s as a method of forming thin sheets of piezoelectric materials and capacitors 1 and is now an accepted precision coating method. Photographs of the hierarchical nanoporous membranes created using a doctor blade coating method A, Photograph of largearea HNM (10 × 10 cm2 ) fabricated by a doctorblade method.

Our services Materials development and optimization for customer coating processes;. JPA Doctor blade, coating apparatus, and method for manufacturing laminated separator Google Patents An object of the present invention is to prevent a doctor blade from being. The coating applicator is either an enclosed chamber with two doctor blades to an open pan with a doctor blade assembly to remove the excess coating In this method all the rolls are turning in the same direction at the point of contact at each nip.

Coating and Varnishing Proact doctor blade chambers produce constant print quality and repeatability, They are manufactured from high strength woven carbon fibre The high strength woven carbon fibre minimises deflection and twisting in the chamber producing more consistent doctoring. Screen and pad printing ;. Common problems caused by lower quality or incorrect type of doctor blades include scoring of the anilox roller and UV ink spitting Using a fitforpurpose doctor blade will prevent issues, and it does not pay off to save on your metering equipment By Neel Madsen Cutting corners is never advisable in flexo printing a process that relies heavily on getting each element right in order for.

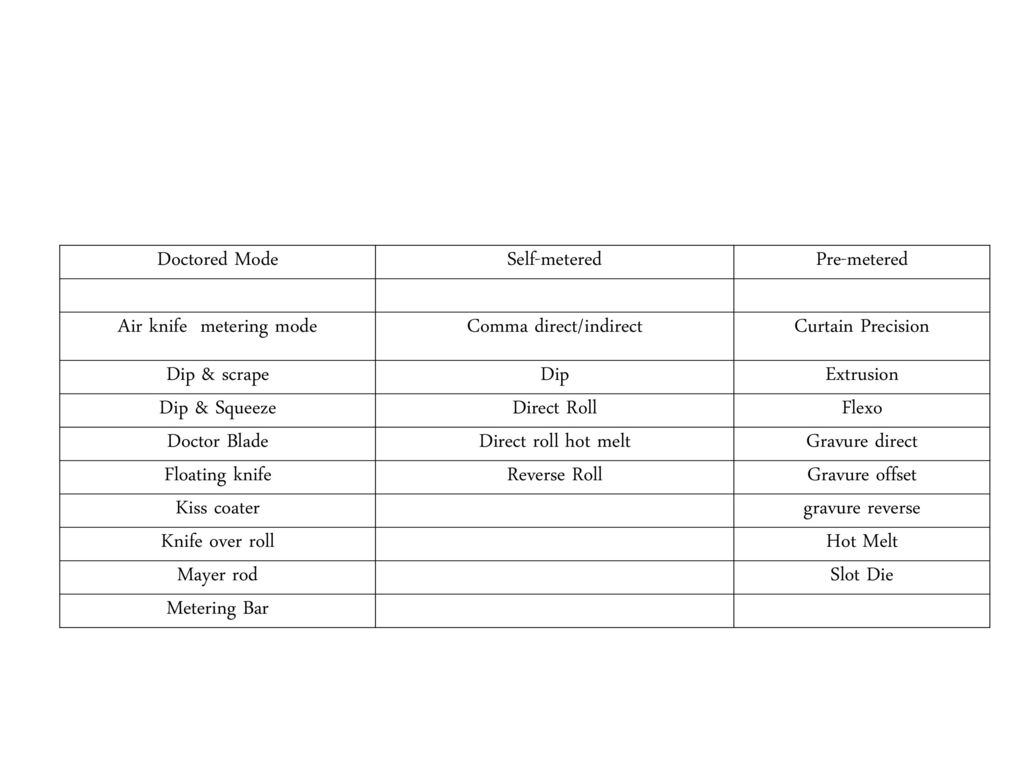

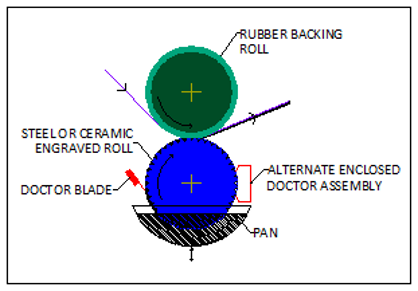

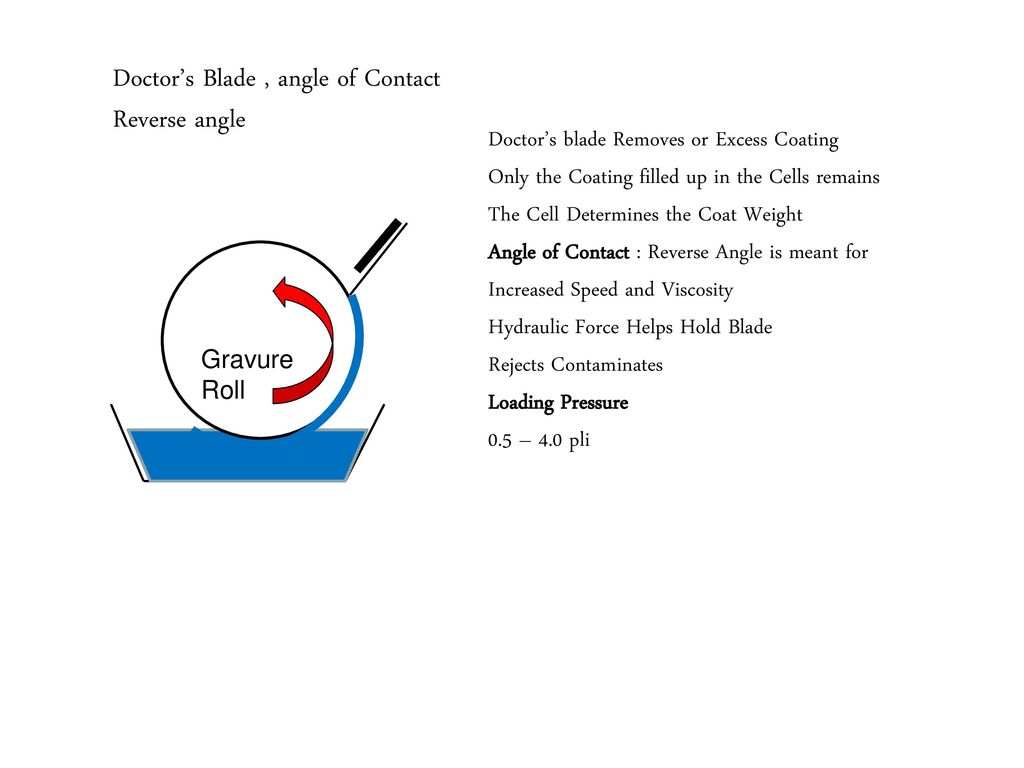

Coating fluid is pooled between the applicator roll and the substrate, and the blade on the roll wipes off excessive fluid to ensure an optimum coating thickness This method is generally suited for highly viscous coating fluids or when forming a thick coating However, some models can support various coating thicknesses Examples of other methods. Gravure Coating The Process The Main Components Coating Tray / Pan Gravure Roller (Etched Metal roller) Doctor Blade Impression Roll (Rubber roller) The Process Pick up of Coating from the Pan Fill up the Cells in the gravure roller Wipe out the excess coating by Doctor Blade Transfer the Coating to the Web Empty the Gravure Cells after Transferring to Web In Gravure Coating method The Applicator Pan or Gravure the Tray Plays a very Roll Important Role The Adhesive level has to be. We have successfully transferred the solution processing of perovskite ink from spin coating to the scalable blade coating method We have studied the proces.

The angle between the blade angle scraper and the tangential line of the anilox roller contact is generally between 15° and 30° If the blade angle of the doctor blade coating machine is too large, the blade is almost against the anilox roller, and the surface of the anilox roller is not smooth When it is running at high speed, it will cause the elastic blade to vibrate or jump, so that the solution is Bounce, so be sure to control the blade angle of the doctor blade coating machinewww. Benefitted from specific crystallization mechanisms, highquality perovskite films with efficient photovoltaic performance in corresponding devices were readily produced either using the bladecoating or even the painting method an average power conversion efficiency (PCE) of 1632% was obtained when using the bladecoating method and up to 16. Doctorblade coating (DBC) is a rolltoroll compatible highthroughput thin film fabrication route with little solution wastage and is considered as a more scalable method for the fabrication of organic solar cells (OSCs) than spin coating (SC) Since wet film drying is much slower during DBC than during SC.

Offset Gravure coating is a coating method consisting of 3 roller and typically an enclosed doctor blade The first roller is a gravure roller with a defined gravure shape and depth On this roller the doctor blade is mounted to apply solvent based, water based or 100% solid coating materials. Doctor and roll cleaning blades are used to clean rolls and remove stock accumulations, water, pitch, and filler buildup With thousands of installations around the globe, our doctoring and roll cleaning technologies offer highperformance cleaning and water removal in a variety of roll cleaning and scraping applications. A set of opaque films were prepared with Degussa P25 ® or Hombikat UV100 ® TiO 2 powders by the doctor blade method on glass slides with different compositions of polyethylene glycol of kDa (PEG), and they were characterized by spectroscopy, microscopy and photochemical kinetics measurements After annealing treatment at 450 °C, about 5–7% C atom was incorporated into the films, as a.

Both tests are performed by scribing the coating to the substrate with a sharp knife blade in a specific pattern, applying a pressure sensitive tape and then rapidly pulling the tape from the surface When the coating is greater than 5mils thick an Xcut (with each leg approximately 15inches long) is made in the film. Gravure printing is a direct printing method in which ink is transferred in cells to the substrate The advantages of gravure printing are a wide application range, high print quality, and large scale printing and anticounterfeit performance High quality coating makes the doctor blade have good corrosion resistance. Doctor blade coated with polymeric material and coating method Patent number Abstract The present invention refers to a doctor blade (1) comprising a metal support (3) completely coated with a polymeric material.

In printing the doctor blade (from ductor blade) removes the excess ink from the smooth nonengraved portions of the anilox roll and the land areas of the cell walls Doctor blades are also used in other printing and coating processes, such as flexo and pad printing for the same function It is believed that the name derives from the blades used in flatbed letterpress equipment for blades used. The nip giving a smooth coating Doctor Blade Applicator roll The three roll reverse coater is used for many specially applications This method is more expensive and generally slower in line speed than the Mayer rod coater However, the versatility in terms of coat weight range and coating width, and the good coat quality of the three roll. Gravure Coating The Process The Main Components Coating Tray / Pan Gravure Roller (Etched Metal roller) Doctor Blade Impression Roll (Rubber roller) The Process Pick up of Coating from the Pan Fill up the Cells in the gravure roller Wipe out the excess coating by Doctor Blade Transfer the Coating to the Web Empty the Gravure Cells after Transferring to Web In Gravure Coating method The Applicator Pan or Gravure the Tray Plays a very Roll Important Role The Adhesive level has to be.

Using too much pressure on the doctor bladebecause of a mechanical issue on the press is one reason to use coated blades Using a coated blade is less likely to cause a burr and can withstand more tension than an uncoated blade If the ability to control the ink film is a result of using too much pressure on the blades, then a MDC Soft Blade. The patented 900 Nano blade is produced by treating the base material to change the steel structure itself thereby eliminating the need for any coating This method increase blade life and reduces friction, and it is an environmentally friendly way of producing long life doctor blades as no toxic waste products are created. Doctor blade (or tape casting) is one of the widely used techniques for producing thin films on large area surfaces Tape casting is a relatively new process which was originally developed during the 1940’s as a method of forming thin sheets of piezoelectric materials and capacitors 1 and is now an accepted precision coat ing method.

Simple and low cost thin film deposition method doctor blade method Cite Popular Answers (1) 21st Nov, 12 Dilek Işik Akcakaya spin coating is the uniform and cheapest method Besides. Improperly used, either mode of doctoring can result in coating carry over due to blade flexure Enclosed, chambered coating applicators feature a combination of powered coating feed and doctor blade metering Coating compound is pumped through the chamber enclosure, via ports designed to optimize the coating distribution Doctor blades are placed at the top and bottom of the applicator, affording total enclosure control of the system. Chambered doctor blade systems form an enclosed ink system by utilizing two doctor blades and two end seals, all running against the anilox roll to contain ink inside the chamber body One of the blades is metering the ink from the anilox roll and is presented to the anilox in a reverse angle orientation.

After the coating fluid on the surface of the gravure roll is wiped off with the doctor blade, the fluid remaining in the pits are transferred onto the web of the target (substrate) Changing the coating thickness requires changing the gravure roll to one engraved with a different pattern. Doctorblade coating (DBC) is a rolltoroll compatible highthroughput thin film fabrication route with little solution wastage and is considered as a more scalable method for the fabrication of organic solar cells (OSCs) than spin coating (SC) Since wet film drying is much slower during DBC than during SC. For the modified doctorblade method, a dense Ti02 paste Dyesensitized solar cell (DSSC) has been known as a was prepared as following Ti02 powder (1 g) was promising photovoltaic device to achieve moderate blended with a mixture of polyethylene glycol (PEG, MW efficiency at ultralow cost 1.

For more information, visit our websitehttp//inbguacil/teva/chem/eng/mennysh/Pages/defaultaspxMusic CreditsIt's Near by Dj QuadsDj Quads on Soundcloud. In printing the doctor blade removes the excess ink from the smooth nonengraved portions of the anilox roll and the land areas of the cell walls Doctor blades are also used in other printing and coating processes, such as flexo and pad printing for the same function It is believed that the name derives from the blades used in flatbed letterpress equipment for blades used to wipe ductor rolls, and "ductor" became doctor A technician installs a doctor blade for flexographic printing. Doctor Blade Coating Machine for Battery Electrode Coating MDTMJ0 is a compact tape casting coater with a heating cover designed to produce films with consistent thickness It has a unique driving system to produce smooth coating on all types of materials The flat vacuum chuck is built in to hold substrate sheet in place, which is particularly useful when making thin coatings.

Doctor blade (or tape casting) is one of the widely used techniques for producing thin films on large area surfaces Tape casting is a relatively new process which was originally developed during the 1940’s as a method of forming thin sheets of piezoelectric materials and capacitors and is now an accepted precision coating method. 1 290mm L x 210mm width x mm Thick flat tempered glass plate 2 One 210 mm width Micrometer Adjustable Film Applicator is included, with adjustable thic.

Formation Of Blade And Slot Die Coated Small Molecule Multilayers For Oled Applications Studied Theoretically And By Xps Depth Profiling Aip Advances Vol 6 No 6

Knife Coating An Overview Sciencedirect Topics

Thin Film Processing Method Part 1

Doctor Blade Coating Method のギャラリー

Automatic Film Coater Doctor Blade Youtube

Knife Coating An Overview Sciencedirect Topics

Hd Flexo Doctor Blades High Demand High Definition Flxon

A Schematic Of The Doctor Blade Setup Reprinted With Permission From Download Scientific Diagram

Versatile Roll To Roll Pilot Coating System With Optional Doctor Blade Reverse Comma Tape Cast Slot Die Micro Gravure Coating Heads Msk Afa Mc400

Technical Coatings International Capabilities

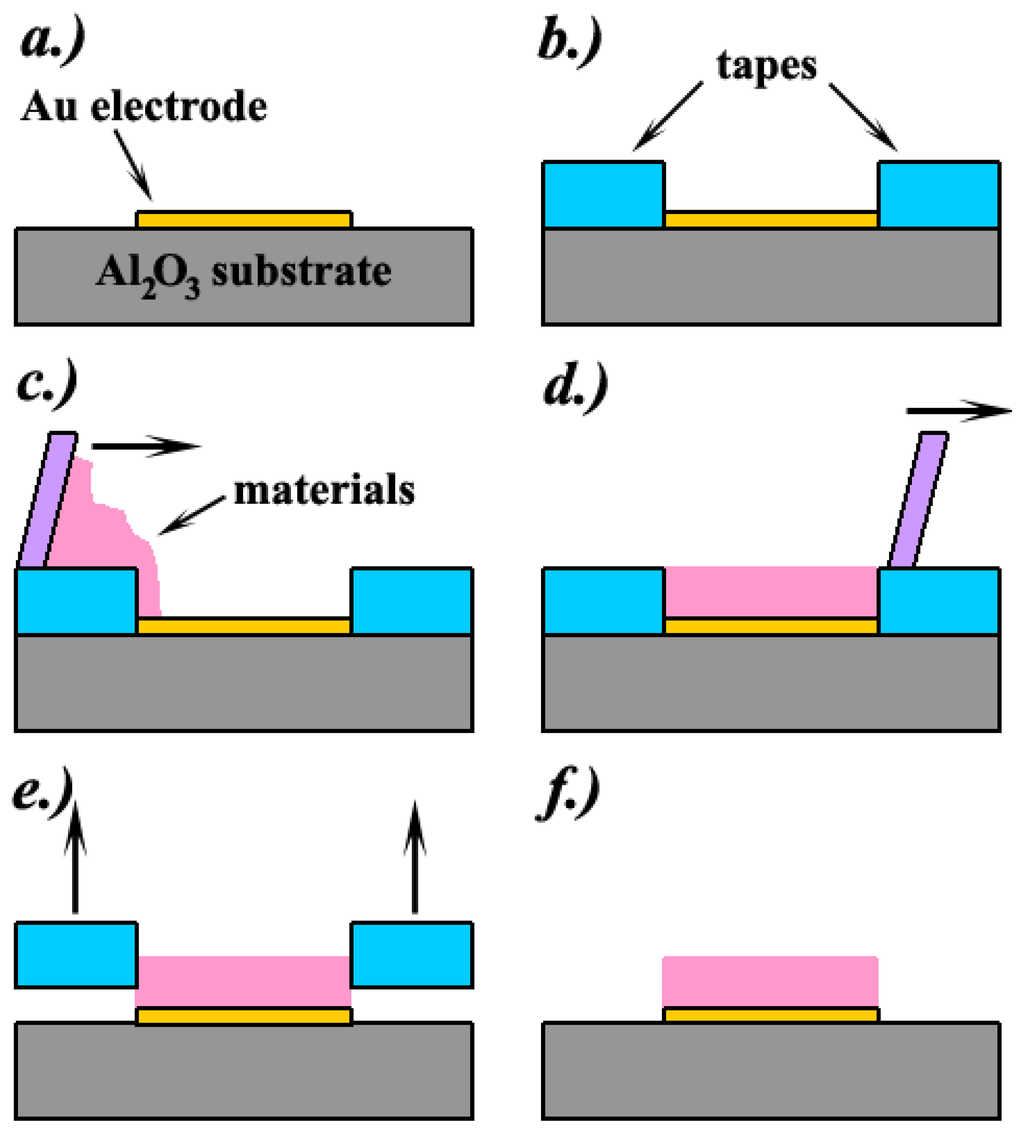

Sensitive Material Deposition Protocol According To A Doctor Blade Method Download Scientific Diagram

Tailoring Solvent Coordination For High Speed Room Temperature Blading Of Perovskite Photovoltaic Films Science Advances

150mm Adjustable Film Coating Applicator Film Coater With Micrometer Wet Film Preparation Device 0 3500mm Width Film Casting Doctor Blade Amazon Com

12 Efficiency In Doctor Blade Coated Organic Solar Cells Through Optimizing The Surface Morphology Of A Zno Cathode Buffer Layer Journal Of Materials Chemistry A Rsc Publishing

Schematic Representation Doctor Blade Technique And Photograph Of Download Scientific Diagram

Doctor Blade Materials And Profiles Pamarco

Metals Free Full Text Major Impediment To Highly Efficient Stable And Low Cost Perovskite Solar Cells Html

Thin Film Processing Method Part 1

The Role Of Physical Techniques On The Preparation Of Photoanodes For Dye Sensitized Solar Cells

Doctor Blade Wikipedia

Knife Coating An Overview Sciencedirect Topics

Organic Solar Cells All Made By Blade And Slot Die Coating Techniques Sciencedirect

Doctor Blade Materials And Profiles Pamarco

Surfactants For Smoother Films Nature Energy

Morphology Control Strategies For Solution Processed Organic Semiconductor Thin Films Energy Environmental Science Rsc Publishing Doi 10 1039 C4ee006g

Soap Film Coating High Speed Deposition Of Multilayer Nanofilms Scientific Reports

Doctor Blade Pt Victory Blessings Indonesia

Figure 4 Photoelectrode Fabrication Of Dye Sensitized Nanosolar Cells Using Multiple Spray Coating Technique

Plastic Doctor Blade Archives Flexo Concepts

Scalable Fabrication Of High Quality Crystalline And Stable Fapbi 3 Thin Films By Combining Doctor Blade Coating And The Cation Exchange Reaction Nanoscale Rsc Publishing Doi 10 1039 C8nrh

Hybrid Film Applicator Doctor Blade 150mm Slot Die 100mm Heads Eq Hds 150 Youtube

Gravure Coating Method For Protective Film Labels Coating Gs Coater

Doctor Blade For Rotogravure Printing Coating Machine Doctor Blade For Rotogravure Printing Manufacturer From Noida

12 Efficiency In Doctor Blade Coated Organic Solar Cells Through Optimizing The Surface Morphology Of A Zno Cathode Buffer Layer Journal Of Materials Chemistry A Rsc Publishing

Challenges And Approaches Towards Upscaling The Assembly Of Hybrid Perovskite Solar Cells Materials Advances Rsc Publishing Doi 10 1039 D0mag

150mm Stainless Steel Adjustable Film Coating Applicator Film Coater With Micrometer Wet Film Preparation Device Removable Magnetic Suction Film Casting Doctor Blade Amazon Com

Microwave Processed Copper Zinc Tin Sulphide Czts Inks For Coatings In Solar Cells Springerlink

Fabrication Of Zno Thin Film Through Chemical Preparations Intechopen

Why Is A Doctor Blade Important Youtube

Lab Compact Polymer Coating Coater With Doctor Blade Suppliers Price Lab Compact Polymer Coating Coater With Doctor Blade For Sale

Scalable Fabrication Of High Quality Crystalline And Stable Fapbi3 Thin Films By Combining Doctor Blade Coating And The Cation Exchange Reaction Nanoscale Rsc Publishing

Polymers Free Full Text Pedot Pss In Water And Toluene For Organic Devices Technical Approach Html

Our Three Commitments Product Information Fuji Shoko Co Ltd

An Overview Of Roll Coating New Era Converting

Versatile Roll To Roll Pilot Coating System With Optional Doctor Blade Reverse Comma Tape Cast Slot Die Micro Gravure Coating Heads Msk Afa Mc400

A Review On Coating Methods For Adhesives By Shrikant Athavale Ppt Download

Gravure Coating Equipment New Era Converting

China Heating Coating Tester Direct Sublimation Paper Coating Machine Doctor Blade Coater China Paper Coating Maichine Paper

Doctor Blade Pt Victory Blessings Indonesia

Large Scale Deposition Of Organic Solar Cells Ossila

A Schematic Diagram Of Doctor Blade Technique B Fe Sem Download Scientific Diagram

Versatile Roll To Roll Pilot Coating System With Optional Doctor Blade Reverse Comma Tape Cast Slot Die Micro Gravure Coating Heads Msk Afa Mc400

Special Effects Doctor Blades Meter Higher Viscosity Inks Coatings More Effectively Flexographic Technical Association

Laboratory Doctor Blade Film Coater Coating Machine With Heat And Vacuum Function For Sale Manufacturers Suppliers Tmax Battery Equipments Limited

Thin Film Coating Solution Processing Techniques Compared Ossila

Doctor Blade Technique And Three Electrode Setup Download Scientific Diagram

Polymers Free Full Text Pedot Pss In Water And Toluene For Organic Devices Technical Approach Html

Latest Review Of Coating Methods 2 Oct 16

A Review On Coating Methods For Adhesives By Shrikant Athavale Ppt Download

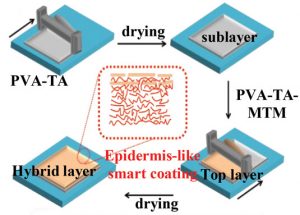

Creating A Scalable Strategy For Self Healing Skins Advanced Science News

Doctor Blade Method For Coating 10 Download Scientific Diagram

Sensors Free Full Text Improvement Of Flame Made Zno Nanoparticulate Thick Film Morphology For Ethanol Sensing Html

Improvement On The Performance Of Perovskite Solar Cells By Doctor Blade Coating Under Ambient Condition With Hole Transporting Material Optimization Sciencedirect

Technical Coatings International Capabilities

Lab Facilities Multifunctional Materials Composites Mmc Laboratory

Blade Coating Of Hybrid Perovskite Solar Cells Acs Energy Letters Youtube

A Generalized Crystallization Protocol For Scalable Deposition Of High Quality Perovskite Thin Films For Photovoltaic Applications Guo 19 Advanced Science Wiley Online Library

Special Effects Doctor Blades Meter Higher Viscosity Inks Coatings More Effectively Flexographic Technical Association

Doctor Blade Archives Flexoglobal Blog

China Doctor Blade For Paper Coating Machine China Coating Machine Scraper Scraper

Valmet S Blade Coating Station

Doctor Blading Materials Processing Britannica

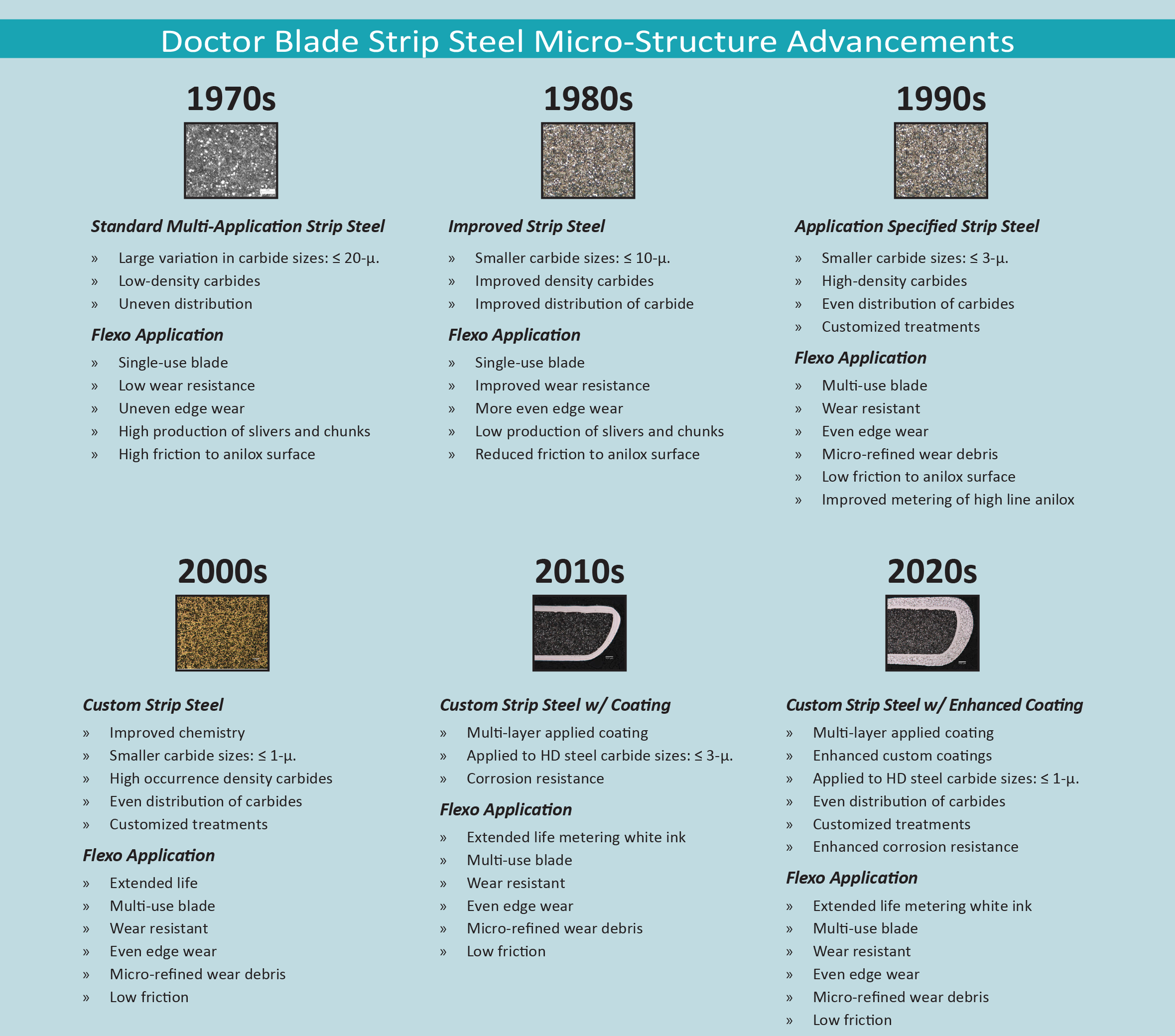

Refining Doctor Blade Technology Flxon

Thin Film Coating Solution Processing Techniques Compared Ossila

Doctor Blade Technique Download Scientific Diagram

Hd Flexo Blades Manualzz

Doctor Blade Metering

Defect Tolerant Perovskite Solar Cells From Blade Coated Non Toxic Solvents Journal Of Materials Chemistry A Rsc Publishing

Doctor Blade Seals Advanced Supplies

Thin Film Coating Solution Processing Techniques Compared Ossila

Yasui Seiki In Usa Roll To Roll Precision Custom Coating Machines

Doctor Blade Coated With Polymeric Material And Coating Method Patent

Doctor Blade Method Explained Youtube

Thin Film Coating Solution Processing Techniques Compared Ossila

12 Diagrams Of The A Spin Coating And B Doctor Blade Coating Download Scientific Diagram

Latest Review Of Coating Methods 2 Oct 16