Doctor Blade Method

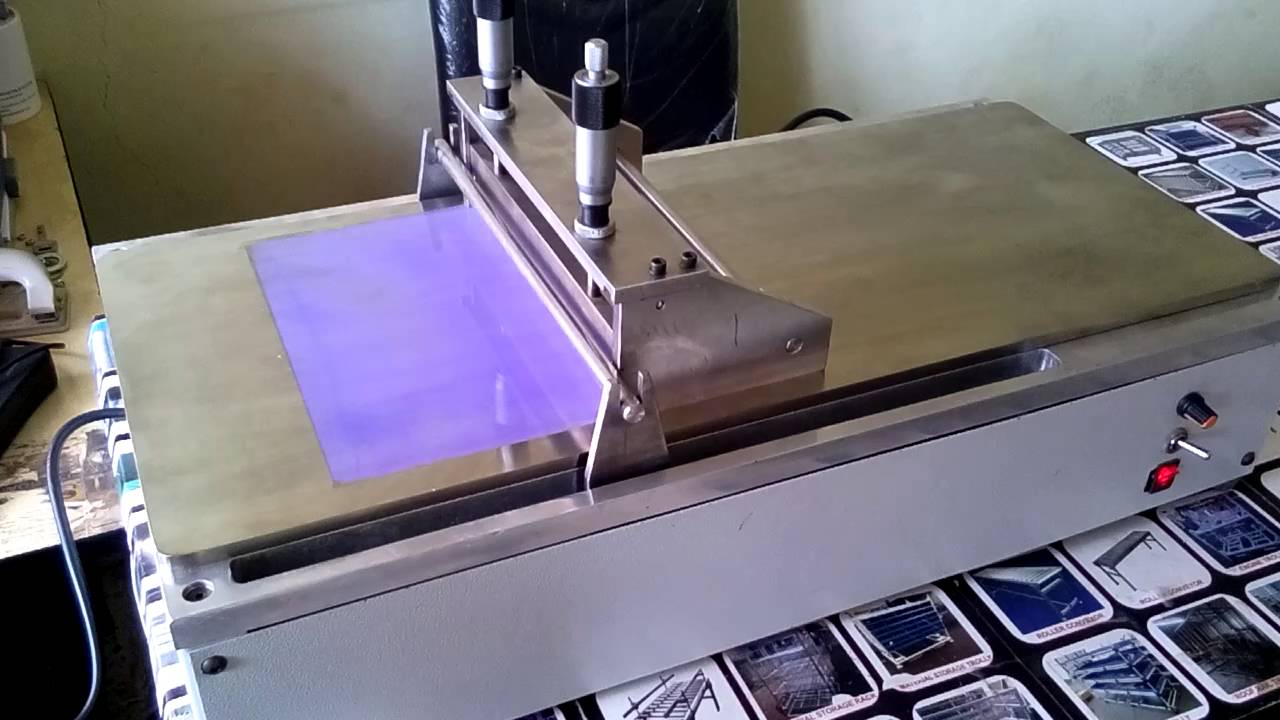

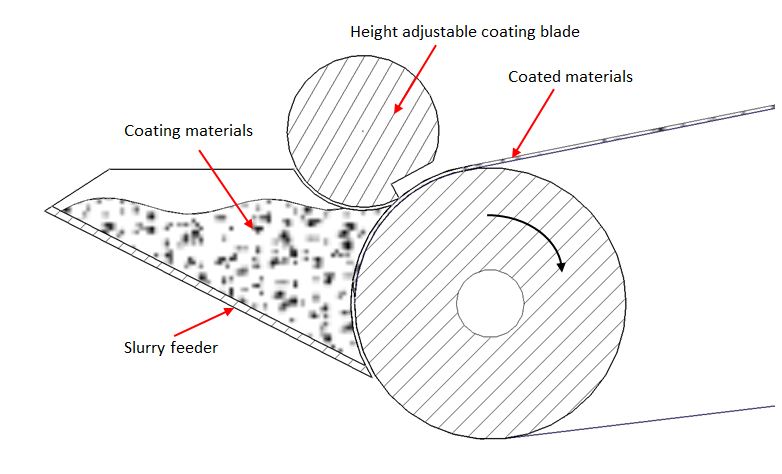

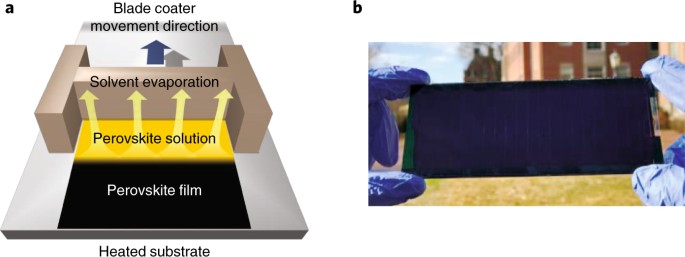

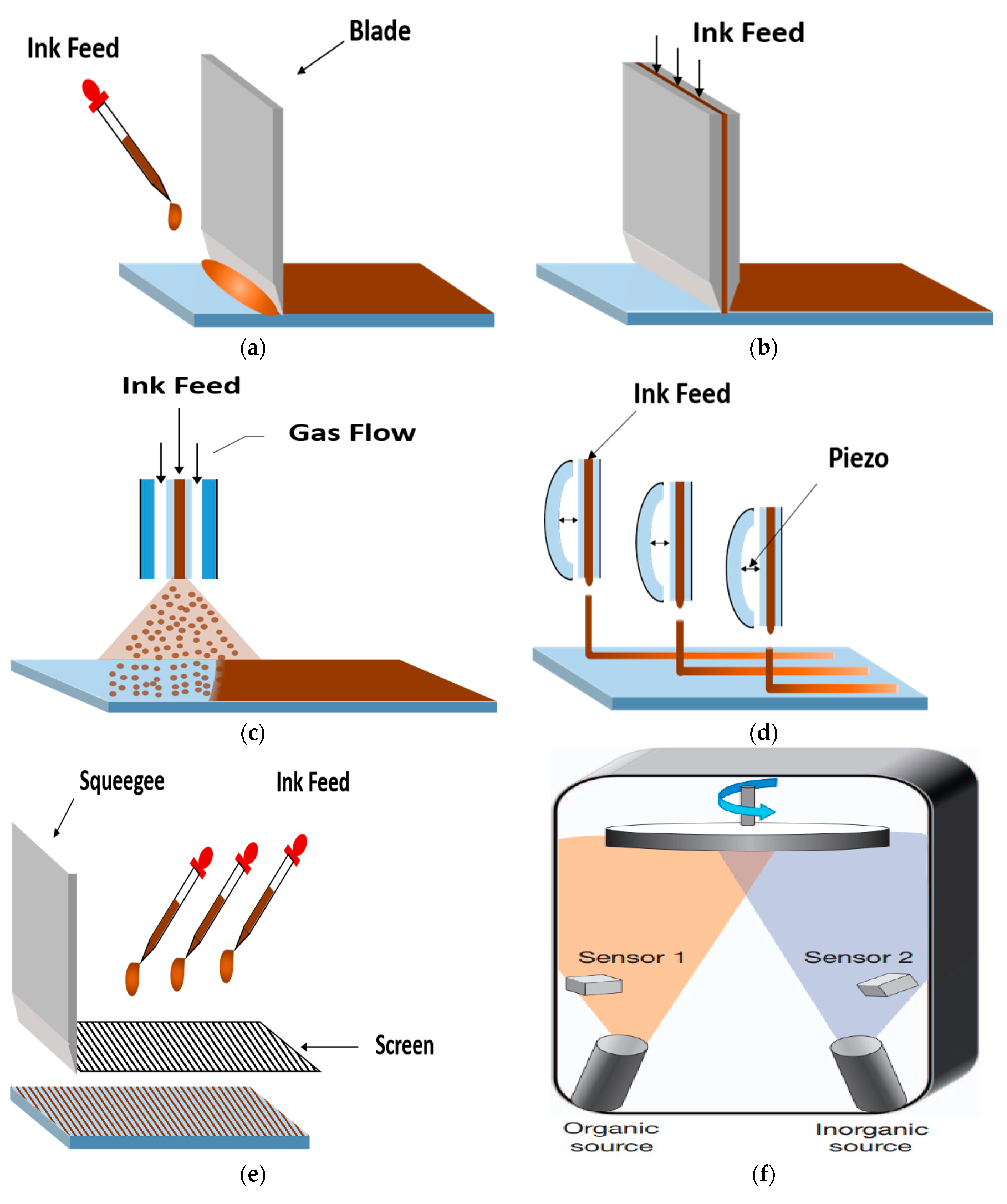

Doctor blading also known as knife coating or blade coating is a popular thinfilm fabrication technique It involves either running a blade over the substrate or moving a substrate underneath the blade There is a small gap that determines how much solution can get through Here, solution is effectively spread over the substrate.

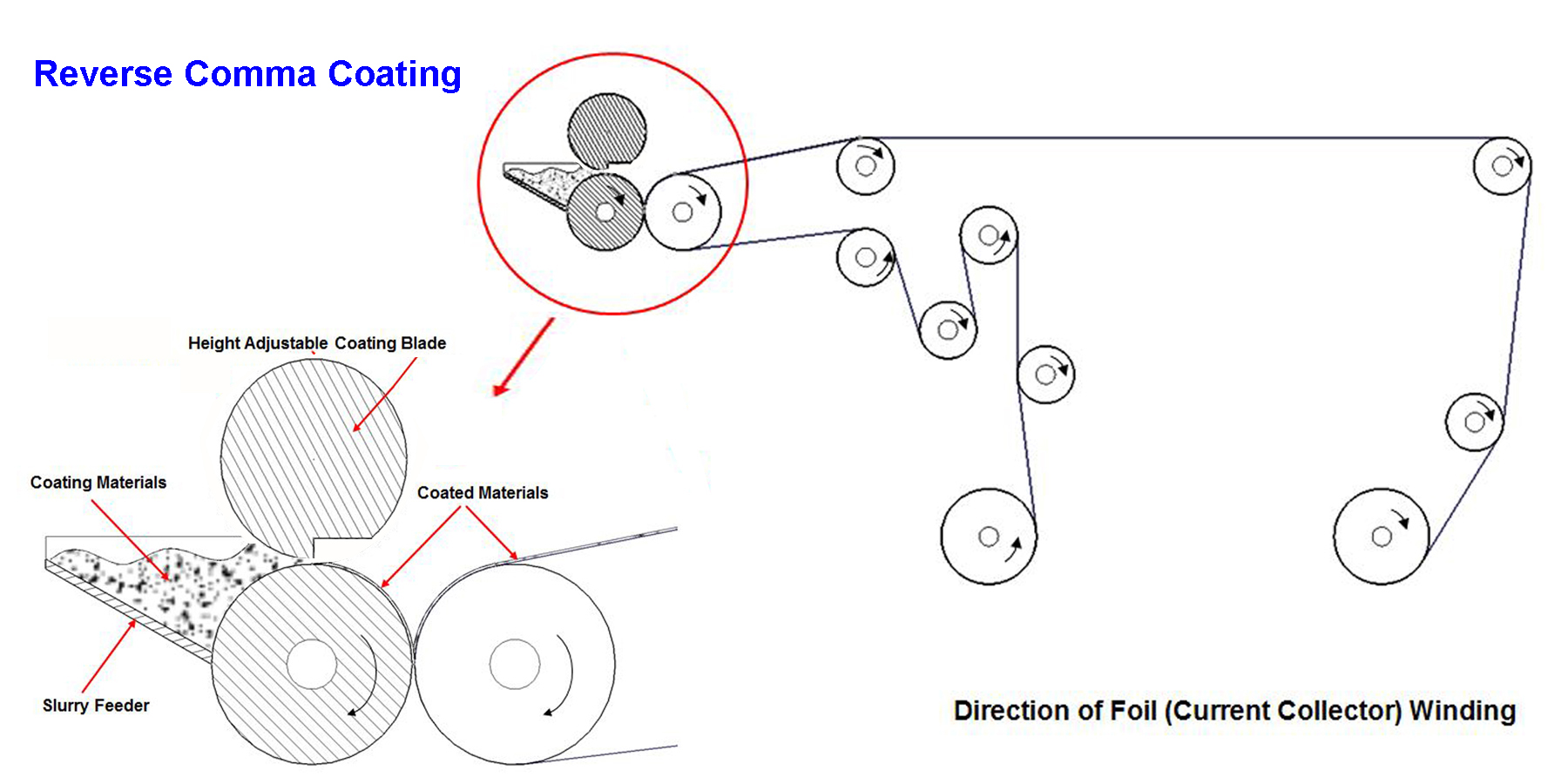

Doctor blade method. Doctor blade method c Calendering d chillroll extrusion e transfer molding f spinning g blown film extrusion process c calendering d chillroll extrusion g blownfilm extrusion process. Plates or films were prepared by the doctorblade method Because of the high viscosity of GalPs, they were spread over the entire substrate surface by a blade before using the doctorblade apparatus In a typical experiment, GalP (GO) was heated to about 40°C and a small quantity was then spread thinly over a Teflon plate by a stainless. Doctor blade (or tape casting) is one of the widely used techniques for producing thin films on large area surfaces Tape casting is a relatively new process which was originally developed during the 1940’s as a method of forming thin sheets of piezoelectric materials and capacitors 1 and is now an accepted precision coating method.

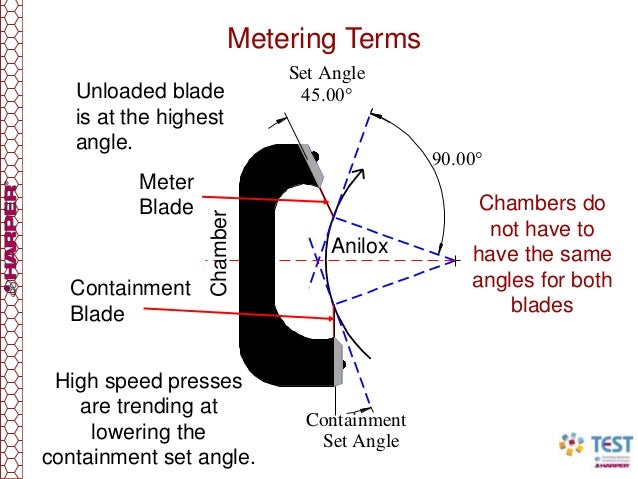

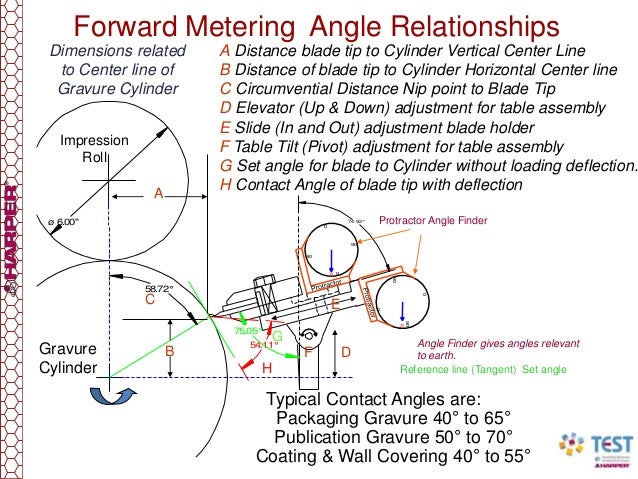

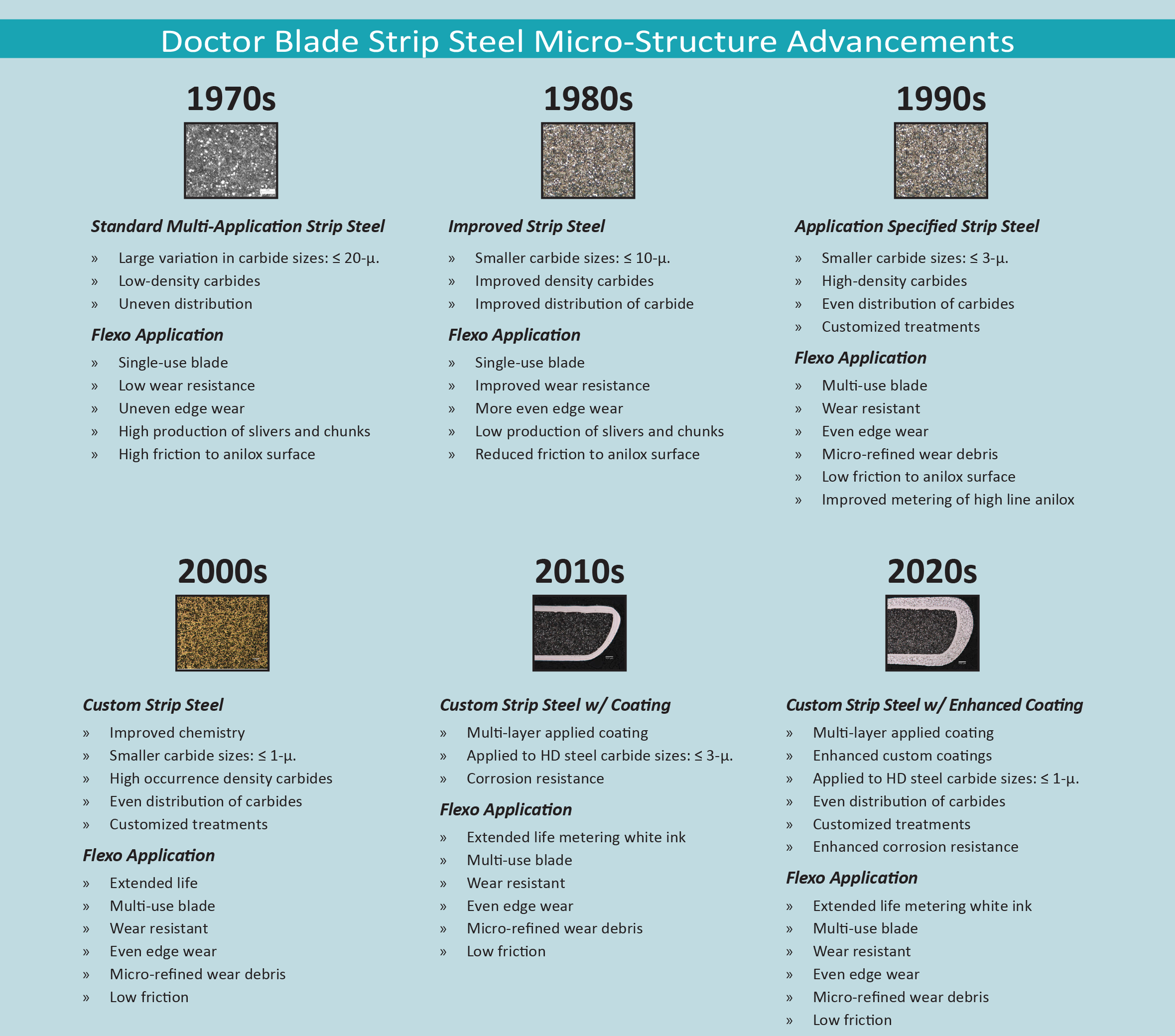

As the doctor blade scrapes (or meters) away the excess ink from the anilox roll, it then coats a precise film of ink onto a printing plate The amount of ink reaching the plate determines the accuracy of the printed image on the film, paper or corrugated substrates See illustration above. Within each toner cartridge is a series of components that work together to deliver you flawless prints This video showcases the doctor blade, and the impor. Methods for doctor blade measurement and setup are provided, as well as basic doctor blade troubleshooting information The appendix is a blade troubleshooting chart based on recognizing blade wear patterns (The scope of this paper does not include creping or coating blades Additionally, the paper uses as.

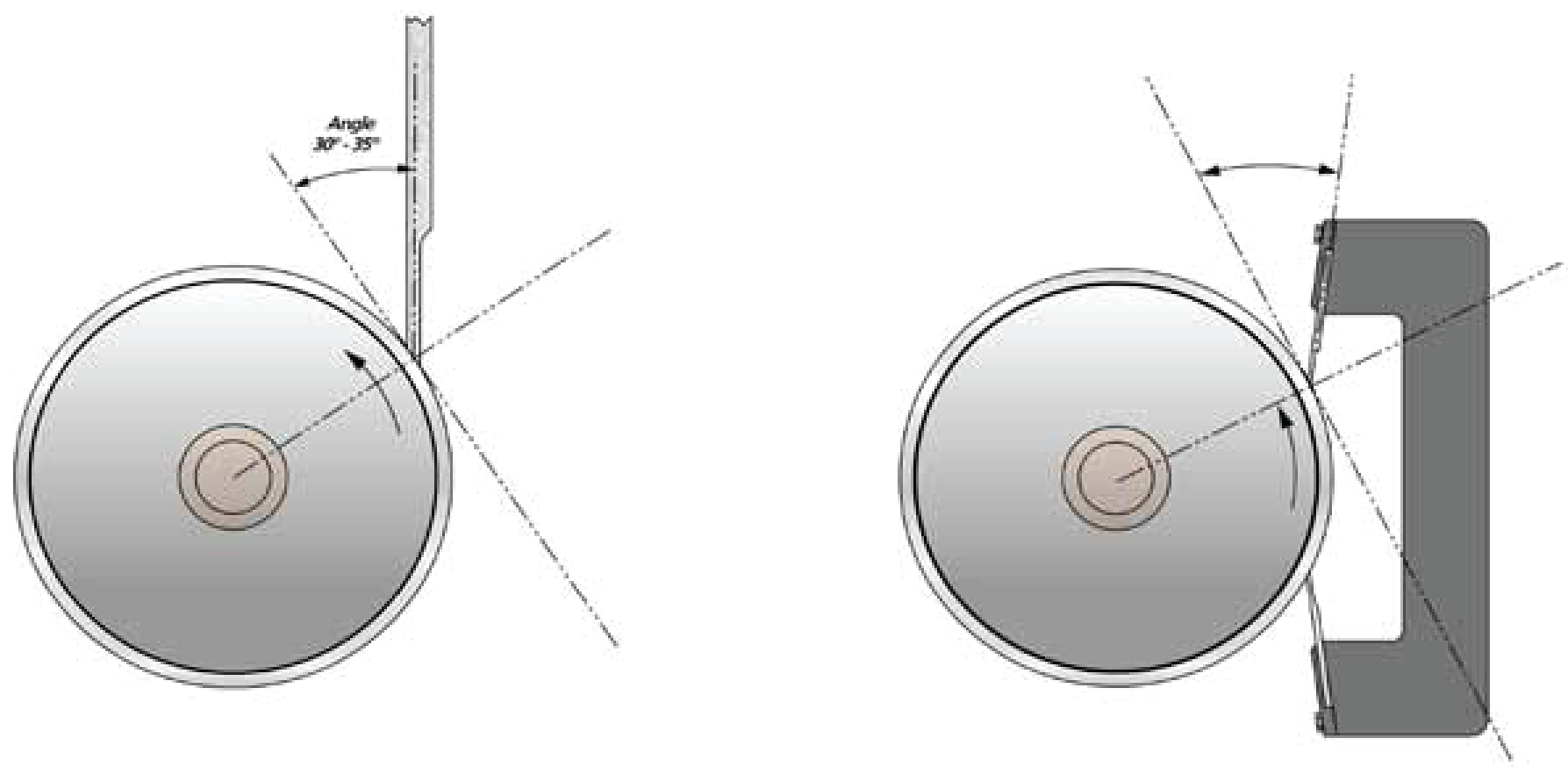

To leave behind a perfectly smooth ink film for transfer to the image on the plate and to do this without damaging the anilox The most precise and even metering takes place when the blade makes contact with the anilox in the reverse or sheering position at an angle between 30° – 35°. The team crafted hydrothermal carbonization of pinewoodbased cellulose mixed with graphene oxide (GO) to create membranes based on an extremely simple doctorblade method Generally, the method is. Prepared by doctor blade method using a colloidal solution of titanium oxide with particles of 15 nm in size The films were transparent in the visible range and well colored in a solution of 1M LiClO 4 in propylene carbonate The transmittances of the colored films were found to be strongly dependent on the Li inserted charges The response.

By solgel method with doctor blade technique for dye sensitized solar cell Was prepared by doctor blade technique The TiO 2 powder 7990 % was mixed into 01 M nitric acid (HNO 3) solution adding DI water until pH 3 – 4 completely and added Triton X100 for surfactant Based on was coated on TCO glass by doctor blade technique. Crepe blade Fixed doctor blade running the width of the Yankee in the creping position This forms the other element of the mechanical components of creping Yankee coating A mix of naturally occurring pulp by products (lignins, hemicelluloses) and applied chemicals which form a thin sticky layer on the Yankee. Doctor Blades are actually an essential part of commercial printing While there are many methods of printing, there are two predominant methods that use Doctor Blades They are called Rotogravure (gravure), and Flexographic (flexo) printing In both Gravure and Flexo printing, the doctor blade is technically a metering blade.

Doctors blade method is used for making thin layers, and I think it is not possible to make thin films with this technique, because thin films are normally deposited by chemical or physical vapor. 137 Which of the following processes are used to produce plastic sheet and film (three correct answers) (a) blown film extrusion process, (b) calendering, (c) chill roll extrusion, (d) doctor blade method, (e) spinning, (f) thermoforming, and (g) transfer molding?. He also says that since every print shop is different, a method should be determined for replacing blades, and whether it's daily or weekly, it should be consistent Stamey goes on to explain that if an anilox is changed "plus or minus more than 100 line screen," the doctor blade should always be replaced 3 Choose The Chamber Wisely.

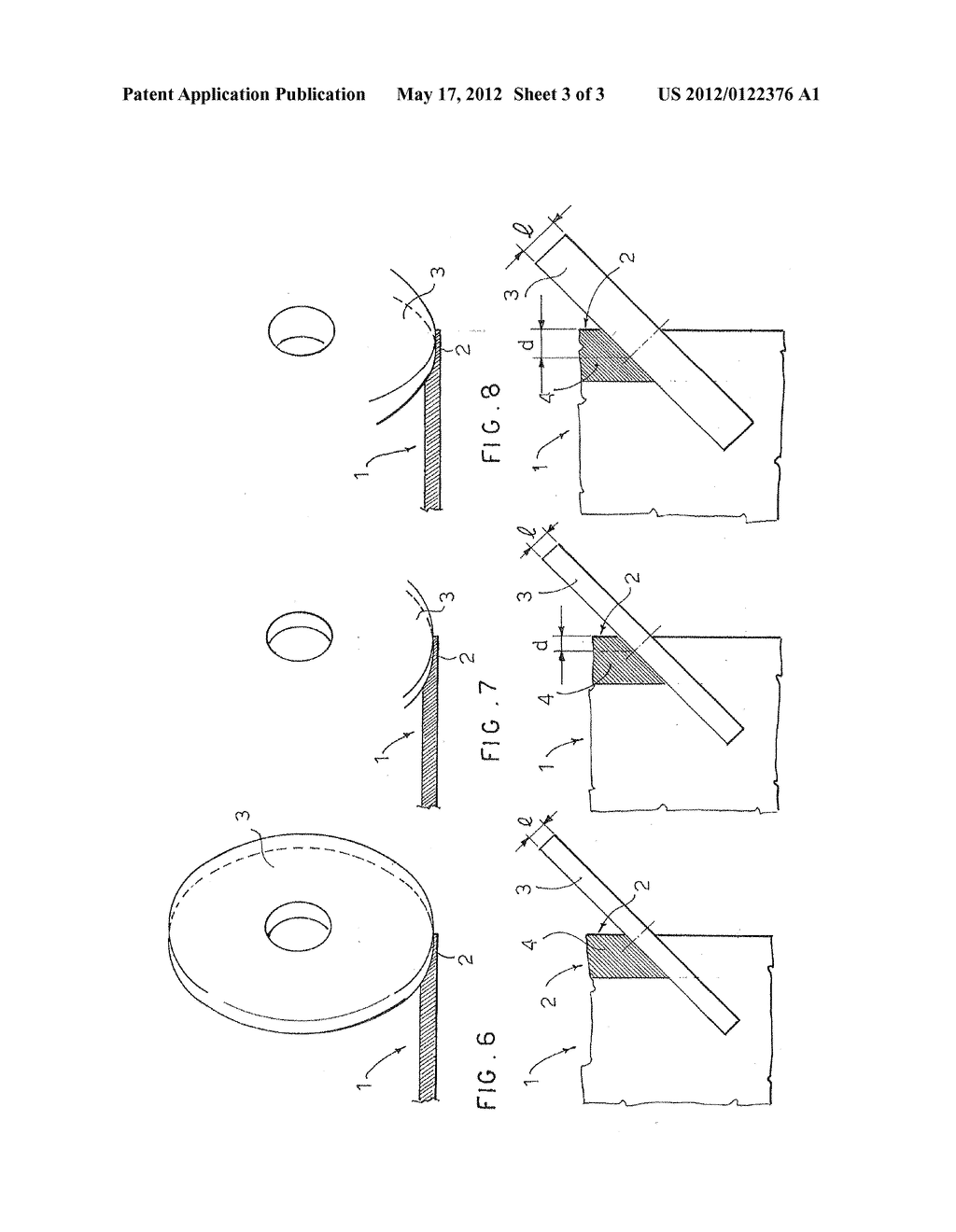

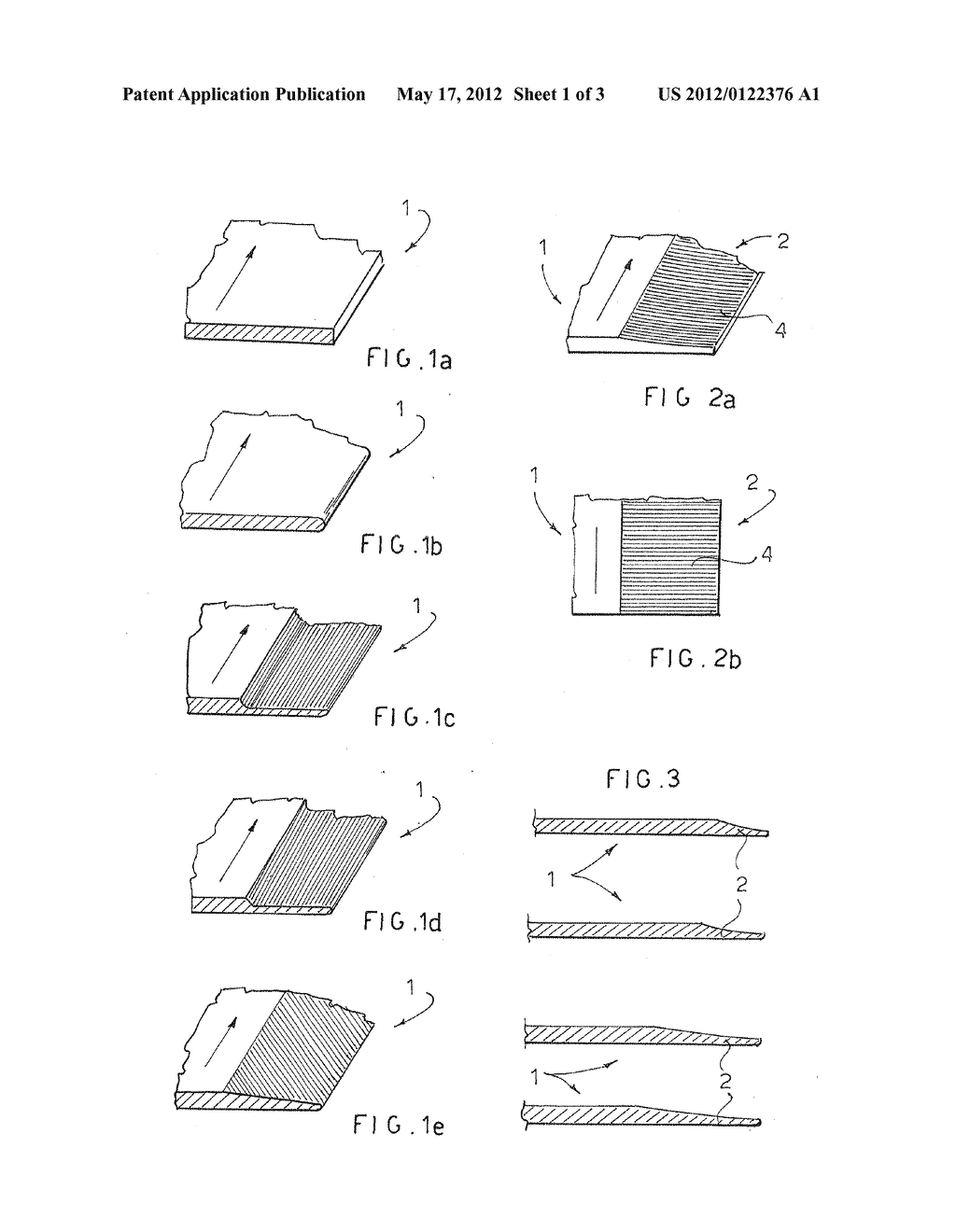

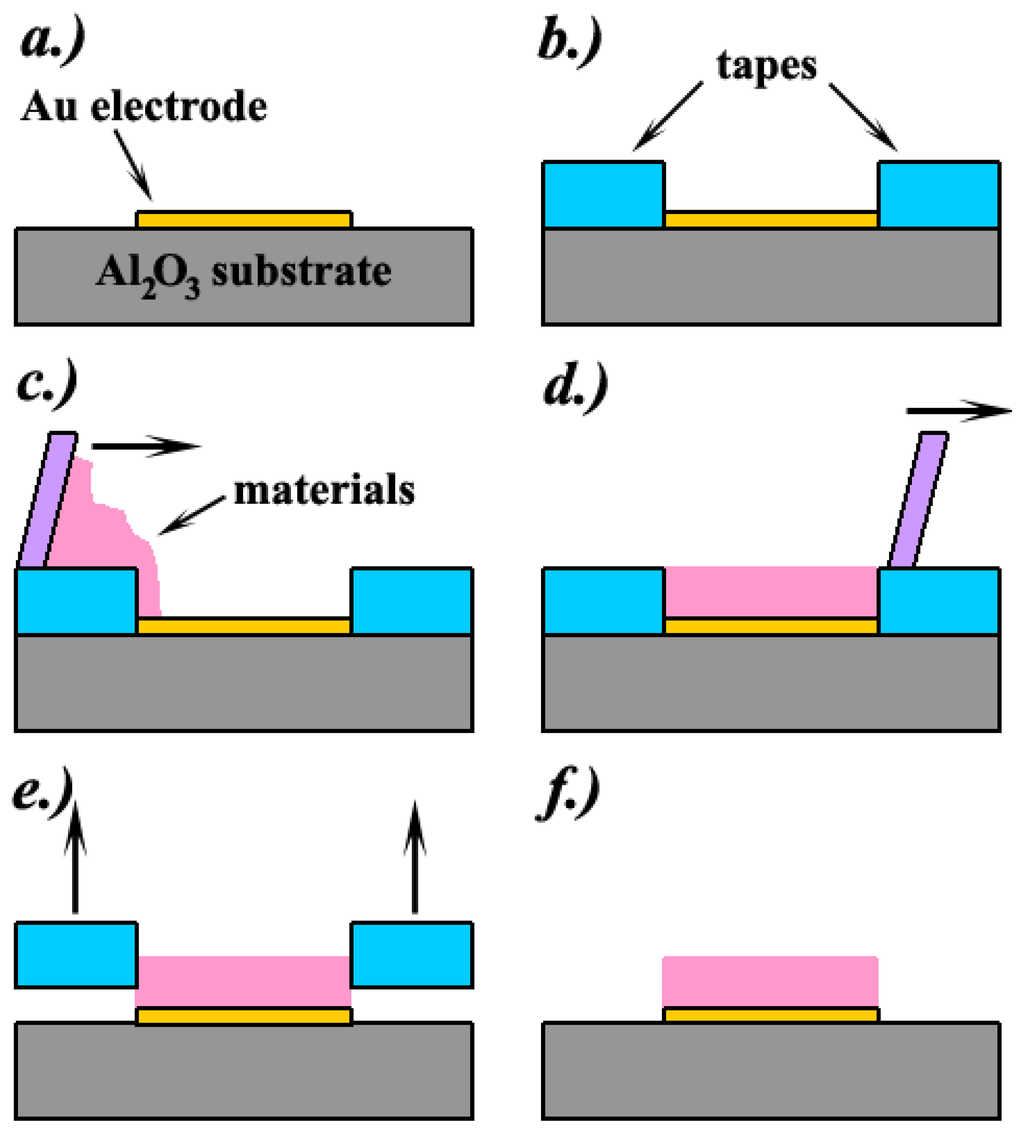

The welldefined thickness of films fabricated using the doctor blade technique is detailed in Figure 3 This method, aptly named tape casting, knife coating, or knifeoveredge coating, due to transfer to reelto reel coating (R2R), is also viable to be used to make films for polymer solar cells The stages of this technique are summarized as. A method of lessening or preventing coverage comprising the steps of placing a doctor blade in contact with a surface of a rotating cylinder, reciprocating the doctor blade generally transverse to the direction of cylinder rotation, and automatically and repetitiously increasing and decreasing doctor bladecylinder contact pressure in response to the transverse reciprocation of the doctor blade thereby lessening or preventing coverage. For more information, visit our websitehttp//inbguacil/teva/chem/eng/mennysh/Pages/defaultaspxMusic CreditsIt's Near by Dj QuadsDj Quads on Soundcloud.

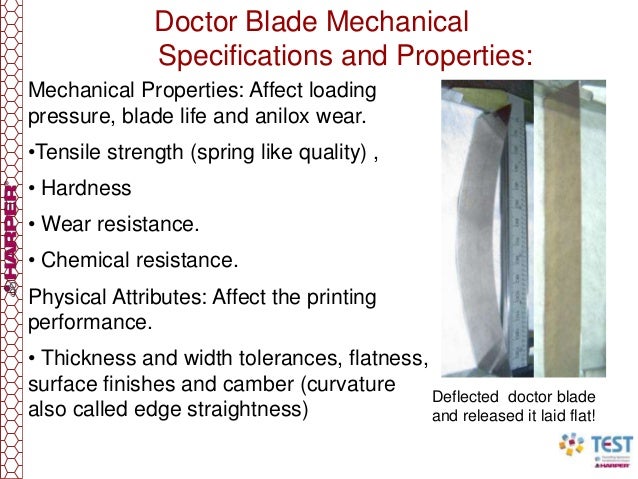

With a higher blade angle To reduce doctor blade force and wear at cylinder ends cut backup blade/ counter blade at an angle at each end Upper cut (at the red line) in backup/ counter blade must stop min 10– mm from cylinder end at full oscillation on each side Effect is lost if the cut point does not always stay on the cylinder surface area. Doctor blade manufacturers have found a way to make new polymer doctor blade materials that can overcome the limitations of steel in specialty coating applications By engineering a modified lamella tip, known as a “MicroTip”, on these materials, they have introduced a doctor blade product that offers the best of traditional plastic and steel Why do they work?. Prepared by doctor blade method using a colloidal solution of titanium oxide with particles of 15 nm in size The films were transparent in the visible range and well colored in a solution of 1M LiClO 4 in propylene carbonate The transmittances of the colored films were found to be strongly dependent on the Li inserted charges The response time of the.

Steps in doctor blading, a tapecasting process employed in the production of ceramic films Ceramic powder and solvent are mixed to form a slurry, which is treated with various additives and binders, homogenized, and then pumped directly to a tapecasting machine There the slurry is continuously cast onto the surface of a moving carrier film. The fully enclosed chamber means reduced solvent evaporation and very important a cleaner, safer working environment for machine operators The doctor blade chamber system offers the latest "toolless" feature for fast blade and end seal changes reducing down time Monoblade chambers designs are also available. A method for the manufacture of the doctor blade of a fiber web machine, where the fiber material used in the composite structure of the doctor blade is impregnated by means of a matrix material and after this the composite structure is hardened, wherein the fiber material is essentially free from carbon fiber and that particulate carbon is added to the composite structure before the composite structure is hardened.

Doctor blades are traditionally designed in 3 main tip configurations straight, bevel and lamella A straight doctor blade has a straight, blunt edge and is used for lower quality print A beveled doctor blade is cut at an angle creating a beveled edge A lamella tip is a doctor blade with a unique geometry that is thin at the tip, gradually becoming larger in a step pattern or other design. A method for the manufacture of the doctor blade of a fiber web machine, where the fiber material used in the composite structure of the doctor blade is impregnated by means of a matrix material and after this the composite structure is hardened, wherein the fiber material is essentially free from carbon fiber and that particulate carbon is added to the composite structure before the composite structure is hardened. Most doctor blade metering systems are preset to position the blade at the optimum contact angle It is much easier to maintain the angle in a single blade system like those common to the label printing industry However, chambered blade metering systems are a challenge.

The doctor blade was used to apply the LTCC slurry At this time, the gap between the blade and the conductor pattern was adjusted to 300 μm After filling, the specimen was kept at room temperature for 24 hours, and then dried at 100°C for 3 hours The flat fine conductor pattern was finally formed on the LTCC green sheet. Doctor Blade for Gravure Printing Gravure printing is a direct printing method in which ink is transferred in cells to the substrate The advantages of gravure printing are a wide application range, high print quality, and large scale printing and anticounterfeit performance. He also says that since every print shop is different, a method should be determined for replacing blades, and whether it's daily or weekly, it should be consistent Stamey goes on to explain that if an anilox is changed "plus or minus more than 100 line screen," the doctor blade should always be replaced 3 Choose The Chamber Wisely.

Our Doctor Blades are available in all different edge types, standard thicknesses and widths They are supplied in 100 meter / 328 foot rolls in easytouse cassettes, or cut in lengths to meet your needs The preground blades have radiusground edges, enhancing blade functionality The blade and cylinders last longer than conventional blades. I need to make optimization for doctor blade technique used to deposit TiO2 mesoporous film used in sensitized solar cell The optimization process I would like to do includes 1 constant thickness. In a doctor blade mechanism including a doctor blade in contact with a surface of a rotating cylinder and means for reciprocating the doctor blade generally transverse to the direction of cylinder rotation, the improvement comprising means operative in response to the transverse reciprocation of said doctor blade for automatically and repetitiously increasing and decreasing doctor bladecylinder contact pressure thereby lessening or preventing coverage.

Most doctor blade metering systems are preset to position the blade at the optimum contact angle It is much easier to maintain the angle in a single blade system like those common to the label printing industry However, chambered blade metering systems are a challenge. A doctor blade is a mechanical device used to remove excess ink from a printing cylinder While it removes some ink, it allows some to stay on the cylinder, thus metering the amount of ink that leaves the cylinder As with most metallic devices, they are subject to wear and corrosion Corrosionpedia explains Doctor Blade. Doctors blade method is used for making thin layers, and I think it is not possible to make thin films with this technique, because thin films are normally deposited by chemical or physical vapor.

Doctor blades are traditionally designed in 3 main tip configurations straight, bevel and lamella A straight doctor blade has a straight, blunt edge and is used for lower quality print A beveled doctor blade is cut at an angle creating a beveled edge A lamella tip is a doctor blade with a unique geometry that is thin at the tip, gradually becoming larger in a step pattern or other design. A set of opaque films were prepared with Degussa P25 ® or Hombikat UV100 ® TiO 2 powders by the doctor blade method on glass slides with different compositions of polyethylene glycol of kDa (PEG), and they were characterized by spectroscopy, microscopy and photochemical kinetics measurements. A method for the manufacture of the doctor blade of a fiber web machine, where the fiber material used in the composite structure of the doctor blade is impregnated by means of a matrix material and after this the composite structure is hardened, wherein the fiber material is essentially free from carbon fiber and that particulate carbon is.

A set of opaque films were prepared with Degussa P25 ® or Hombikat UV100 ® TiO 2 powders by the doctor blade method on glass slides with different compositions of polyethylene glycol of kDa (PEG), and they were characterized by spectroscopy, microscopy and photochemical kinetics measurements After annealing treatment at 450 °C, about 5–7% C atom was incorporated into the films, as a. With a higher blade angle To reduce doctor blade force and wear at cylinder ends cut backup blade/ counter blade at an angle at each end Upper cut (at the red line) in backup/ counter blade must stop min 10– mm from cylinder end at full oscillation on each side Effect is lost if the cut point does not always stay on the cylinder surface area. He also says that since every print shop is different, a method should be determined for replacing blades, and whether it's daily or weekly, it should be consistent Stamey goes on to explain that if an anilox is changed "plus or minus more than 100 line screen," the doctor blade should always be replaced 3 Choose The Chamber Wisely.

The three methods, in order of increasing effectiveness, are fountain roll metering, singleblade systems and chambered systems Most applications are better served with either a single blade or chambered doctor blade system This article will provide a comparison of the singleblade and chambered doctor blade systems. HD FLEXO Doctor Blades – High Demand/High Definition By Paul Sharkey, FLXON The core purpose of a doctor blade in the flexo process is to remove excess ink from the anilox surface;. Even though the doctorblade coating technique has been widely used to prepare PSCs, it is yet to be applied to highefficiency PSCs under ambient conditions (RH∼45%, RT∼25 °C) In this study, we conducted bladecoating fabrication of modified highefficiency PSCs under such conditions.

Blade loading There are four basic methods of loading a doctor, they are 1 Mechanical spring 2 Pneumatic/Hydraulic cylinder 3 Gravity 4 Holder loaded (hose loaded doctor blade holder), doctor locked by turnbuckles NOTE The crosssection of any doctor beam is very small in comparison to its length The result of this is. The original woven carbon fiber dualblade system 2G Chamber The next evolution in single wiper blade systems The world’s first onpress ultrasonic anilox cleaner Achieving an 80% reduction in ink loss Products We are Absolute, specialists in ink doctoring and ink management for the flexo industry Think Challenge. Smestad, 1998) and by inkjet printing technology (described as inkjet printed photodetector, IPP) to be used in conjunction with the Aunanoprobe based method.

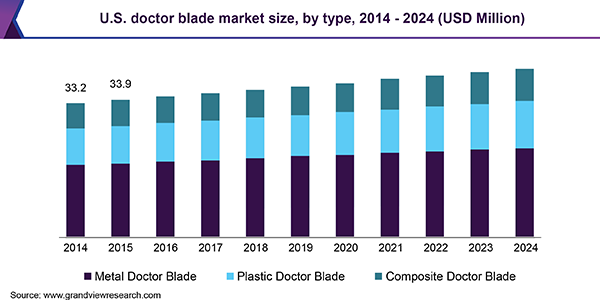

Doctor blade (or tape casting) is one of the widely used techniques for producing thin films on large area surfaces Tape casting is a relatively new process which was originally developed during the 1940’s as a method of forming thin sheets of piezoelectric materials and capacitors and is now an accepted precision coat ing method. HD DOCTOR BLADE Like all flexo process components, the doctor blade has evolved to the point that many blade materials, commonly used in 1980, are no longer available To understand the driving forces in this evolution, it’s important to first review the fundamental function of a doctor blade. JPA Doctor blade, coating apparatus, and method for manufacturing laminated separator Google Patents An object of the present invention is to prevent a doctor blade from being.

We developed a disposable biosensor integrating a dye sensitized TiO 2 photodetector obtained by standard “doctor blade” method (from now on referred as “doctor blade” photodetector, DBP;. Switching to thin, wider blades Usually done on the containment side of the chamber, press crews will employ this method as a quick fix As the press continues to run, however, this actually allows for unwanted ink debris to more easily pass under the extended, wider blade—causing a number of more severe and unwanted issues. The doctor blade is a component that wipes away excess ink and similar material from moving parts Essentially, it ensures the clean and precise transfer of inks in highspeed printing processes It is a smart addition to a press since it leads to consistent, quality results.

When it comes to doctor blades, a thicker blade will often result in a narrower contact area A thicker blade had better resist flexing when pressure is applied Consider the gain seen in Chart 2 when moving from 0006in thickness to 0008in—that’s 33 percent more material There are three types of doctor blade tips. Doctor and roll cleaning blades are used to clean rolls and remove stock accumulations, water, pitch, and filler buildup With thousands of installations around the globe, our doctoring and roll cleaning technologies offer highperformance cleaning and water removal in a variety of roll cleaning and scraping applications. Many translated example sentences containing "doctor blade method" – GermanEnglish dictionary and search engine for German translations.

Our designed doctorblade method shows the advantages of highly versatile, uniform, and freestanding membranes with a precisely controlled thickness Figure 5B shows freestanding and flexible HNM. Doctor Blades are actually an essential part of commercial printing While there are many methods of printing, there are two predominant methods that use Doctor Blades They are called Rotogravure (gravure), and Flexographic (flexo) printing In both Gravure and Flexo printing, the doctor blade is technically a metering blade. A doctor blade that’s installed correctly will have uniform, balanced contact with the anilox roll and remove ink consistently across its surface Blade positioning, orientation, angle and pressure will affect the delivery of a precise amount of ink to the plate, and proper installation will give the printer control over consistent, repeatable print quality.

The term "doctor blade" is believed to be derived from the name of a blade used in conjunction with ductor rolls on letterpress presses The term "ductor blade" eventually mutated into the term "doctor blade" In gravure printing, the doctor blade is a steel strip used to remove ink from the outside surface of the gravure cylinder Although. Doctor & Roll Cleaning Blades Doctor and roll cleaning blades are used to clean rolls and remove stock accumulations, water, pitch, and filler buildup With thousands of installations around the globe, our doctoring and roll cleaning technologies offer highperformance cleaning and water removal in a variety of roll cleaning and scraping applications. The blades need to have a long lifespan in order to reduce the change time of doctor blade and increase efficiency Considering the above requirements, we recommend the following doctor blades which have high precision, good durability, long lifespan and are suitable for gravure printing.

Measured Angle Doctor angle can be expressed in two ways ◦ With reference to radial line (BSI), and ◦ With reference to tangential line (ASTM) This method gives angle along tangential line To get angle along radial line, just subtract the angle computed from 90˚ February 14 Determination of Doctor Angle 14 15. The welldefined thickness of films fabricated using the doctor blade technique is detailed in Figure 3 This method, aptly named tape casting, knife coating, or knifeoveredge coating, due to transfer to reelto reel coating (R2R), is also viable to be used to make films for polymer solar cells The stages of this technique are summarized as the movement of a substrate at a constant speed under a blade, with a specific height and contact angle. Anatase thin films on Fdoped tin oxide (FTO) substrates were prepared by doctor blade method using a colloidal solution of titanium oxide with particles of 15 nm in size The films were transparent in the visible range and well colored in a solution of 1M LiClO 4.

For the modified doctorblade method, a dense Ti02 paste Dyesensitized solar cell (DSSC) has been known as a was prepared as following Ti02 powder (1 g) was promising photovoltaic device to achieve moderate blended with a mixture of polyethylene glycol (PEG, MW efficiency at ultralow cost 1.

Schematic Representations Of A The Doctor Blade Method And B The Download Scientific Diagram

Automatic Film Coater Doctor Blade Youtube

Large Scale Deposition Of Organic Solar Cells Ossila

Doctor Blade Method のギャラリー

Iopscience Iop Org Article 10 10 2631 7990 Ab263e Pdf

Versatile Roll To Roll Pilot Coating System With Optional Doctor Blade Reverse Comma Tape Cast Slot Die Micro Gravure Coating Heads Msk Afa Mc400

Www Valmet Com Globalassets Media Downloads White Papers Process Improvements And Parts Wpp Doctoring Pdf

Doctor Blade Metering

Recent Developments Of Graphene Tio2 Composite Nanomaterials As Efficient Photoelectrodes In Dye Sensitized Solar Cells A Review Sciencedirect

Doctor Blading Materials Processing Britannica

Doctor Blade Technique Download Scientific Diagram

Q Tbn And9gcrqfom5eh Obeko84ilmknr8a1hdcdtlimjignpu0llybdjuw5y Usqp Cau

Tape Casting An Overview Sciencedirect Topics

Doctor Blade Synthesis Method Download Scientific Diagram

Fabrication Schema Of The Doctor Blade Method Download Scientific Diagram

Schematic Representation Doctor Blade Technique And Photograph Of Download Scientific Diagram

Www Researchgate Net Profile Mallikarjuna Reddy Kesama Post How To Make A Uniform Thin Film With A Very Simple Method Attachment 5d04bcd1cfe4a7968daae94b As 3a Download Instru Sep Week 2 Pdf

Pre Honed Doctor Blade With A Curved Profile Lamella And Method For Producing Said Doctor Blade Diagram Schematic And Image 04

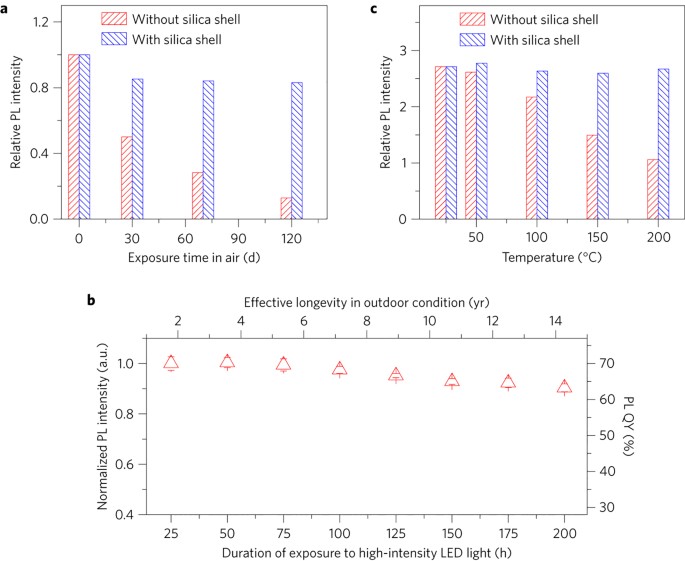

Doctor Blade Deposition Of Quantum Dots Onto Standard Window Glass For Low Loss Large Area Luminescent Solar Concentrators Nature Energy

Pre Honed Doctor Blade With A Curved Profile Lamella And Method For Producing Said Doctor Blade Diagram Schematic And Image 02

Www Spiedigitallibrary Org Proceedings Download Fulldoi 10 1117 2f12

Link Springer Com Content Pdf 10 1007 2f978 0 387 853 5 10 Pdf

Doctor Blade Coated With Polymeric Material And Coating Method Patent

Doctor Blade Metering

Doctor Blade Metering

Deb4 Composite Doctor Blade With Powder Metallurgical Produced Working Edge Google Patents

Doctor Blade Coated With Polymeric Material And Coating Method Patent

Www Researchgate Net Profile Mallikarjuna Reddy Kesama Post How To Make A Uniform Thin Film With A Very Simple Method Attachment 5d04bcd1cfe4a7968daae94b As 3a Download Instru Sep Week 2 Pdf

Doctor Blade Metering

12 Efficiency In Doctor Blade Coated Organic Solar Cells Through Optimizing The Surface Morphology Of A Zno Cathode Buffer Layer Journal Of Materials Chemistry A Rsc Publishing Doi 10 1039 C8ta073j

Aerosol Assisted Chemical Vapor Deposition Of Sb2s3 Thin Films Environmentally Benign Solar Energy Material Sciencedirect

Www Valmet Com Globalassets Media Downloads White Papers Process Improvements And Parts Wpp Doctoring Pdf

Epa1 Pre Honed Doctor Blade With A Curved Profile Lamella And Method For Producing Said Doctor Blade Google Patents

Preparation Of Tio2 Thin Film Using Modified Doctor Blade Method For Improvement Of Dye Sensitized Solar Cell Semantic Scholar

Tampoprnt Academy

A Schematic Of The Doctor Blade Setup Reprinted With Permission From Download Scientific Diagram

New Polymers Meter Like Steel Doctor Blades Flexoglobal Blog

Hd Flexo Doctor Blades High Demand High Definition Flxon

Thin Film Coating Solution Processing Techniques Compared Ossila

Figure 10 Czts Counter Electrode In Dye Sensitized Solar Cell Enhancement In Photo Conversion Efficiency With Morphology Of Tio 2 Nanostructured Thin Films Springerlink

1

Microwave Processed Copper Zinc Tin Sulphide Czts Inks For Coatings In Solar Cells Springerlink

Doctor Blade Selection Guide Dekejie Com

Knife Coating An Overview Sciencedirect Topics

Onlinelibrary Wiley Com Doi Pdf 10 1002 Aenm

Doctor Blade Archives Flexoglobal Blog

Composite Doctor Blade And Method Of Its Production

Scalable Fabrication Of High Quality Crystalline And Stable Fapbi3 Thin Films By Combining Doctor Blade Coating And The Cation Exchange Reaction Nanoscale Rsc Publishing

Sensors Free Full Text Improvement Of Flame Made Zno Nanoparticulate Thick Film Morphology For Ethanol Sensing Html

Doctor Blade Pt Victory Blessings Indonesia

Doctor Blade Method Explained Youtube

Preparation And Transport Properties Of Oriented Buckypapers With Single Walled Carbon Nanotubes

Pdf Fabrication Of Dye Sensitized Solar Cell Using Spray Coating Method Agus Purwanto Academia Edu

Versatile Roll To Roll Pilot Coating System With Optional Doctor Blade Reverse Comma Tape Cast Slot Die Micro Gravure Coating Heads Msk Afa Mc400

Pubs Acs Org Doi Pdf 10 1021 Lav

Hd Flexo Blades Manualzz

Figure 2 From Photocatalytic Degradation Of An Azo Textile Dye C I Reactive Red 195 3bf In Aqueous Solution Over Copper Cobaltite Nanocomposite Coated On Glass By Doctor Blade Method Semantic Scholar

Sensitive Material Deposition Protocol According To A Doctor Blade Method Download Scientific Diagram

Large Area Hysteresis Free Perovskite Solar Cells Via Temperature Controlled Doctor Blading Under Ambient Environment Sciencedirect

Knife Coating An Overview Sciencedirect Topics

Www Valmet Com Globalassets Media Downloads White Papers Process Improvements And Parts Wpp Doctoring Pdf

The Gravure Printing Process Allison Systems

Www Valmet Com Globalassets Media Downloads White Papers Process Improvements And Parts Wpp Doctoring Pdf

Arxiv Org Pdf 1811

Q Tbn And9gcs5fhxjbbqdytiv5bt0vwpc4j9vmyr2cjxaufx9d6s6n0meqshz Usqp Cau

Gallus Ferd Ruesch Ag Printing Machines And Solutions For The Label Printing And Folding Carton Printing Key Factors Influencing Flexographic Printing Part 1 Of 2

Versatile Roll To Roll Pilot Coating System With Optional Doctor Blade Reverse Comma Tape Cast Slot Die Micro Gravure Coating Heads Msk Afa Mc400

Doctor Blade Method For Coating 10 Download Scientific Diagram

Iopscience Iop Org Article 10 10 2631 7990 Ab263e Pdf

Surfactants For Smoother Films Nature Energy

Digital Flexo Photopolymer Plate Flexographic Printing Printing Method

Doctor Blade Deposition Of Quantum Dots Onto Standard Window Glass For Low Loss Large Area Luminescent Solar Concentrators Nature Energy

Global Doctor Blade Market Size Share Industry Report 19 24

Photovoltaic Performance Of A N719 Dye Based Dye Sensitized Solar Cell With Transparent Macroporous Anti Ultraviolet Photonic Crystal Coatings Rsc Advances Rsc Publishing

Gravure Coating Method For Protective Film Labels Coating Gs Coater

Print Method Gravure Melvin Magro

Fabrication Schema Of The Doctor Blade Method Download Scientific Diagram

Q Tbn And9gcqltyimhbqreqo7nffmzyv6q9xmazyk28lvmo0jjrmyvja1xrag Usqp Cau

Refining Doctor Blade Technology Flxon

Doctor Blade Technique And Three Electrode Setup Download Scientific Diagram

The Role Of Physical Techniques On The Preparation Of Photoanodes For Dye Sensitized Solar Cells

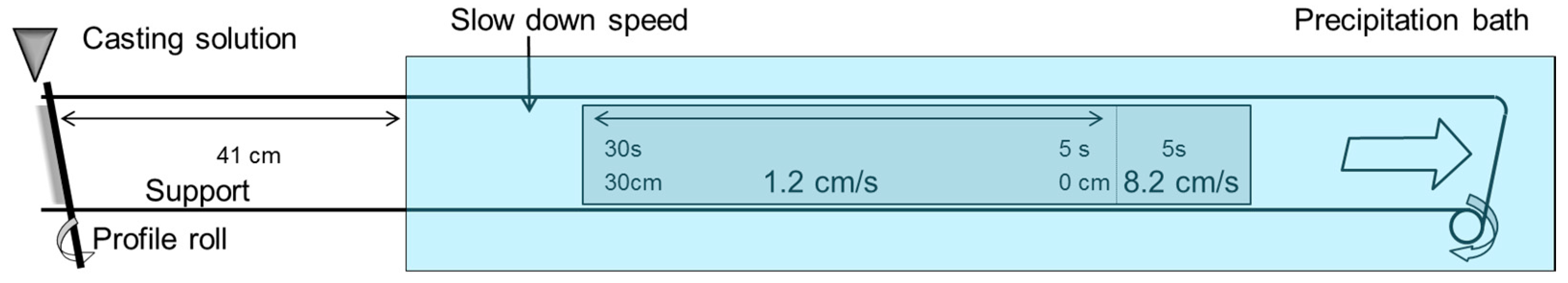

Membranes Free Full Text Formation Of Thin Isoporous Block Copolymer Membranes By An Upscalable Profile Roller Coating Process A Promising Way To Save Block Copolymer Html

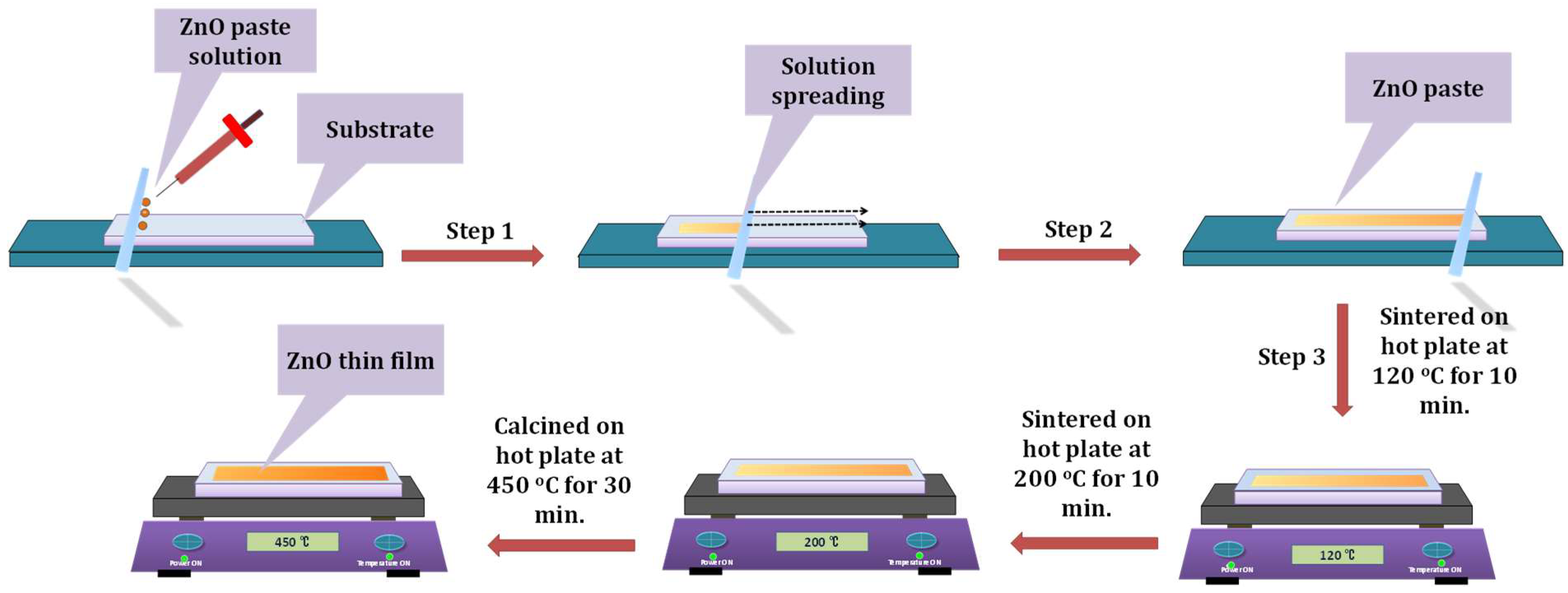

Electronics Free Full Text Solution Processable Zno Thin Film Memristive Device For Resistive Random Access Memory Application Html

Aip Scitation Org Doi Pdf 10 1063 1

Preparation Of Tio2 Thin Film Using Modified Doctor Blade Method For Improvement Of Dye Sensitized Solar Cell Semantic Scholar

A Schematic Diagram Of Doctor Blade Technique B Fe Sem Download Scientific Diagram

Usb2 Apparatus For Measuring The Wear Of A Doctor Blade And Method In Measuring The Wear Of A Doctor Blade And In Controlling A Paper Machine Google Patents

Sensitive Material Deposition Protocol According To A Doctor Blade Method Download Scientific Diagram

Preparation Of Tio2 Thin Film Using Modified Doctor Blade Method For Improvement Of Dye Sensitized Solar Cell Semantic Scholar

Http Iopscience Iop Org Article 10 10 43 6262 4 1 Pdf

Link Springer Com Content Pdf 10 1007 2f978 0 387 853 5 10 Pdf

12 Efficiency In Doctor Blade Coated Organic Solar Cells Through Optimizing The Surface Morphology Of A Zno Cathode Buffer Layer Journal Of Materials Chemistry A Rsc Publishing

Thin Film Coating Solution Processing Techniques Compared Ossila

Hybrid Film Applicator Doctor Blade 150mm Slot Die 100mm Heads Eq Hds 150 Youtube

Metals Free Full Text Major Impediment To Highly Efficient Stable And Low Cost Perovskite Solar Cells Html

Knife Coating An Overview Sciencedirect Topics

Usb2 Apparatus For Measuring The Wear Of A Doctor Blade And Method In Measuring The Wear Of A Doctor Blade And In Controlling A Paper Machine Google Patents

Thin Film Coating Solution Processing Techniques Compared Ossila

Www Osapublishing Org Viewmedia Cfm Uri Jlt 30 21 3316 Seq 0

Www Researchgate Net Profile Mallikarjuna Reddy Kesama Post How To Make A Uniform Thin Film With A Very Simple Method Attachment 5d04bcd1cfe4a7968daae94b As 3a Download Instru Sep Week 2 Pdf

Photocatalytic Efficiency Tuning By The Surface Roughness Of Tio2 Coatings On Glass Prepared By The Doctor Blade Method1 Photochemistry And Photobiology X Mol

Scalable Fabrication Of High Quality Crystalline And Stable Fapbi 3 Thin Films By Combining Doctor Blade Coating And The Cation Exchange Reaction Nanoscale Rsc Publishing Doi 10 1039 C8nrh

Improvement On The Performance Of Perovskite Solar Cells By Doctor Blade Coating Under Ambient Condition With Hole Transporting Material Optimization Sciencedirect

Why Is A Doctor Blade Important Youtube

Www Osti Gov Servlets Purl